Understanding Direct-to-Garment Printing

What is DTG?

Direct-to-Garment (DTG) printing is a go-to solution for high-quality, custom apparel printing. Using advanced inkjet technology, DTG applies water-based inks directly onto fabric, producing vibrant and detailed prints.

What is the DTG Process?

The process of Direct-to-Garment (DTG) printing is relatively straight forward, with light coloured garments, you simple place them in the printer and press print.

When a white under base is required, we pre-treat the fabric before printing:

- Pre-treat the garment by applying a pre-treatment solution to the fabric

- Dry the pre-treatment using heat press or tunnel dryer

- Place the garment on the printer and press print

- Cure the printed inks using a heat.

What can you decorate with DTG?

Direct-to-Garment (DTG) inks bond with garments manufactured from natural fibres, such as, cotton, calico, canvas, denim, hemp, bamboo etc.

DTG is more than just a t-shirt printer, it will work with any type of product that is made from natural fibres that lay flat, some products examples are tea towels, tote bags, jeans, hoodies, shorts, the list is endless.

Exploring the benefits and advantages of DTG printing

Print quality – soft feel of hand

One of the biggest advantages of DTG printing is the exceptional print quality and the ultra-soft feel. The ink is absorbed into the fabric rather than sitting on top which is what happens with any heat transfer processes leaving a thick and crunch feeling. This perceives DTG-printed garments as a premium product and they’re more comfortable to wear.

Any artwork – drop shadows and fades

DTG printing can handle complex artwork with ease, including designs with gradients, fine details, drop shadow and fades. Unlike transfer printing methods, where it can be extremely difficult or near impossible to achieve these effects. DTG seamlessly reproduces detailed designs directly onto the fabric. This makes it ideal for intricate artwork, photo-realistic prints, and designs with subtle shading effects.

Cost effectiveness

DTG is cost-effective as it does not require additional transfer materials. Since DTG prints directly onto fabric, there is no need to produce transfers, cut the transfers, collate the transfers, match the transfers to the garment and then align the transfers on the garment.

DTG allows you to easily calculate your total unit cost as you know exactly how long it is taking you to produce your products.

Durability

When properly cured, DTG prints are extremely durable, maintaining their vibrancy and integrity through multiple washes. The water-based inks used in DTG bond directly with the fabric, ensuring long-lasting results. On the other hand, transfer prints, while also durable, may sometimes be prone to cracking or peeling over time, this is due to water pressure in the wash cycle pushing through the transfer, whereas, with DTG the water will pass through the ink.

On-demand production

On-demand production refers to the process of selling a product and then producing it before supplying it to the customer. This applies whether you’re producing one item per week, a thousand per week, or even ten million per week.

DTG is ideal for this, allowing you to print garments only when needed without any setup costs or time. This eliminates excess inventory, reduces waste, and enables you to offer custom apparel without holding large stock.

Proven technology

Predictability is key to success in business and in our industry, we need to know that when we go to print the printer will print and perform as required. DTG printing has been in use for over two decades and now the large printer manufacturers on their fourth and fifth generation technology. Over time they have continued to improve and refine with advancements in ink formulations, print head technology and automated maintenance processes. The Epson F-Series DTG printers provide you with that predictability you need.

Sustainability

DTG printing is regarded as one of the most, if not the most sustainable print method for decorating garments.

It does not use any harmful chemicals, it uses water-based inks and pretreatment and most importantly it does not use plastic carrier sheet like all transfer print methods. There is also less energy consumed in running the equipment as it a tunnel dryer is not mandator and there’s no external extraction systems required.

Moreover, even if the garments do end up in landfill, they will decompose overtime as they’re made from natural fibres.

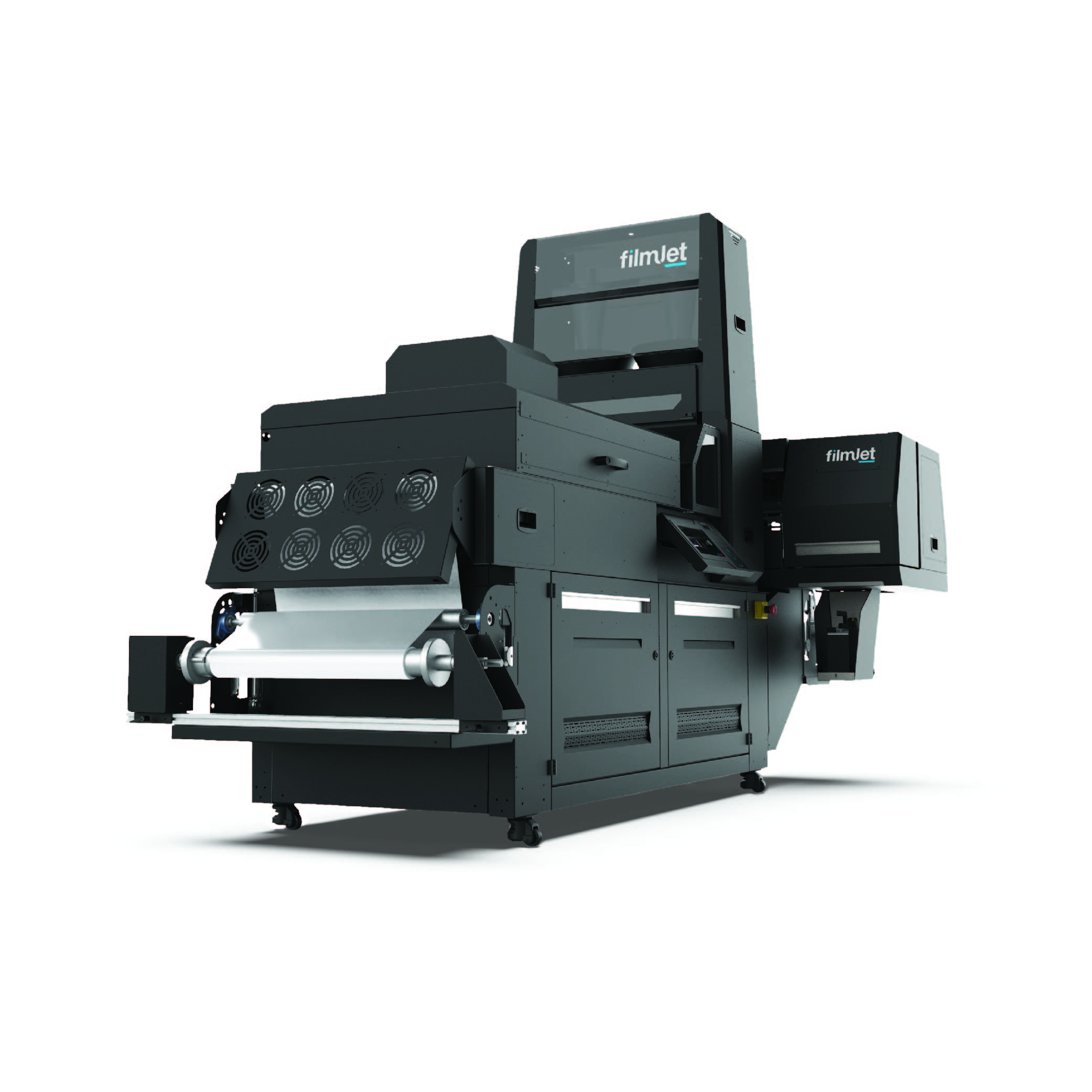

Epson F-Series Range of DTG Printers

The Epson F-Series range of direct-to-garment and direct-to-film printers cater for all businesses, from entry level to high production, there is model to suit your production requirements.

Find out about Epson’s unique benefits and take your business to the next level.