Talk to an expert

For more information or to request a Brochure, call us on 02392 590 281

The Ultimate Solution for Bulk

On-Demand DTG Printing

Kornit systems deliver low cost, exceptional quality printing of over 100 garments per hour with only one operator and with built in Pre-Treatment

Got a demanding garment production process? Streamline it with Kornit, makers of the most advanced direct-to-garment (DTG) systems that provide a single platform to automate your entire garment printing process.

Plus, your printed garments will remain soft to touch and won’t crack or fade thanks to the unique patented water-based inks used in every Kornit system, accredited to the highest standards.

Can we help you?

Superior print quality. Incredible productivity. Easy automation.

Kornit DTG systems really are the future of custom garment printing.

DTG Systems by Kornit Digital

The most advanced Kornit Direct-To-Garment printing solution

- Integrated pre-treatment

- 130 garments w. Activeload*

- Web-to-print-technology

A true mass customisation solution

- Integrated pre-treatment

- 235 garments per hour*

- Web-to-print-technology

The perfect industrial DTG solution for high-volume production

- Integrated pre-treatment

- 160 dark garments per hour*

- Web-to-print-technology

Exceptional cost per print and print quality for medium to large size printing businesses.

- Integrated pre-treatment

- 90 dark garment per hour*

- Web-to-print-technology

Exceptional cost per print and print quality for small to medium size printing businesses.

- Integrated pre-treatment

- 55 dark garment per hour*

- Web-to-print-technology

*all print numbers are based on a dark shirt, an average design of 33x33cm in high productivity print mode, with pre-treatment included.

The smartest and most cost-efficient solution for polyester printing!

- A unique single-step process for both white and dark polyester

- Profitability from the very first print, even for short run printing

- Meet the polyester industry’s high durability standards

- Meets global sustainability requirements

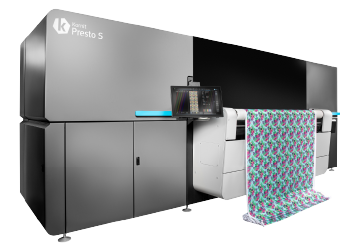

The most advanced single-step solution for high volume direct-to-fabric printing!

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Best Pigment in Market

- Single step process

- Multiple fabric types

- The most sustainable process in the market

Retail Quality Printing at Any Volume

With a production speed of up to 100 garments per hour, a Kornit DTG printer can handle whatever your run volume. Plus, you’ll save hours of time and cut down on errors thanks to its integrated pre-treatment.

With Kornit’s HD systems, you can maximise your revenue by being able to take on even the smallest orders thanks to Kornit’s low cost per print on runs of 1–500.

For a truly sustainable single-step solution for direct-to-fabric (DTF) printing, the Kornit Presto S has you covered with its high-quality prints, vivid colours and great hand feel on multiple fabrics on demand.

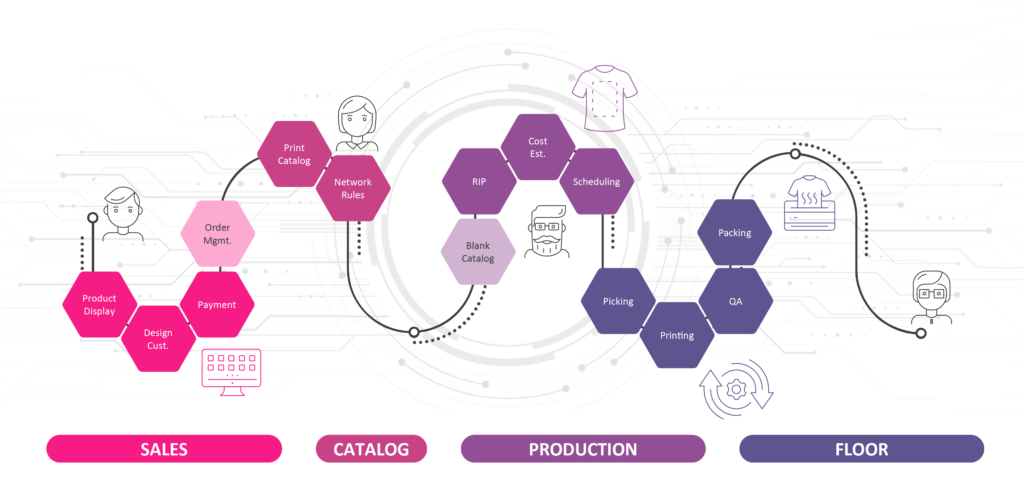

Kornit Workflow Solution

End-to-End Production Workflow

Kornit workflow is an end-to-end web to print solution that enables orders of customised, personalised and on demand products from order to despatch. The tools and services offered make it easier for companies to source, create, manage, sell and fulfill drop ship products.

5 Steps to owning a Kornit

#Kornitroadmap

Kornit’s water-based NeoPigment™ inks are non-hazardous and non toxic. The waterless printing system makes printing with Kornit an eco-friendly solution to help protect our planet for the future.

- 100% non hazardous

- 100% Toxin free

- Contain no animal by-products

- Safe for infants and babies

Meets the highest regulation standards.

Our Vision

Why Kornit Workshop

Register your interest now for our free DTG Kornit Workshop at our Nottingham Showroom.

Sustainability

Sustainability is no longer an optional extra; the consumer and the planet demand change.

Waterless

Water is the very essence of life, a precious resource that must be conserved. That’s why Kornit produces zero water waste and provide a sustainable print pathway to serve the world’s textile printing industry at any scale.

Reduced Energy

Digital technologies use a fraction of the energy of traditional textile print routines. The earth is saturated with toxic carbon, 10% of which can be attributed to fashion industry production alone.

Cleaner Chemicals

Kornit inks are environmentally-friendly and safe for the skin and children. Trust in our ongoing dedication to providing green chemistry and a future safe pathway for an equally green planet.