DTG or DTF Printing?

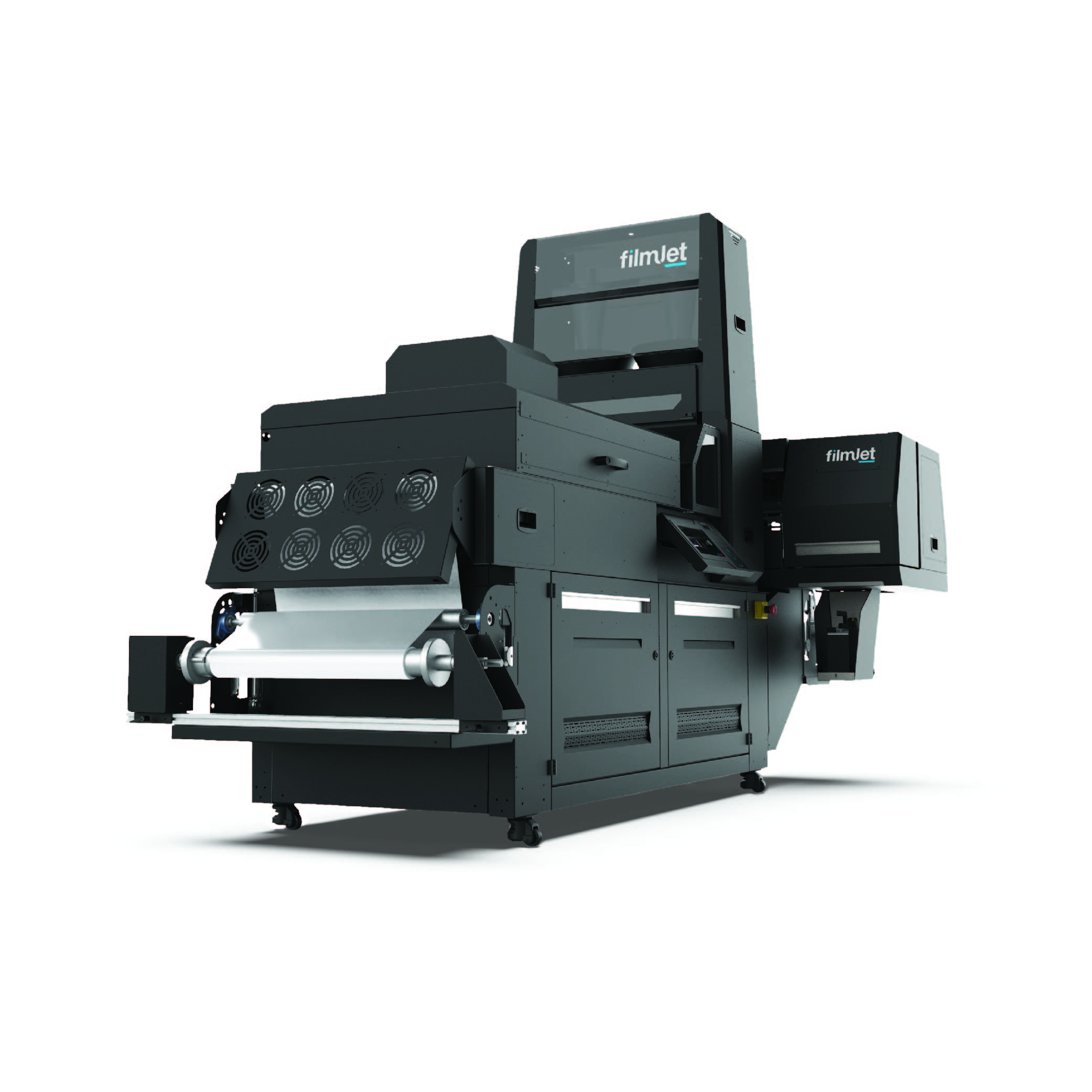

One of the latest buzz words I am hearing today is the term “DTF printing” with reference to Direct to Film printing. Options are becoming available from consumable packs of film and glue that are compatible with certain DTG printers, right through to fully automated solutions that can take up to 3 meters in space.

As the different options become more readily available, there is a school of thought out there who are saying DTF will take over from DTG, and DTG will no longer be needed as a means of garment decoration.

I strongly disagree with this. Firstly, 2021 data shows a continued growth in the sale of DTG printers worldwide, both at entry and industrial level. Secondly, I believe, that like all forms of garment decoration, there is a place for both processes in the market and I will explain why by looking at the key features of both methods. These for me fall under four key headings – Speed, Hand-Feel, Fabric Type and Sustainability.

DTG Printing

Speed

Because DTG prints directly onto the fabric I would argue the process is slightly quicker than DTF production at entry level, and much faster at an industrial level. In both cases you do not need to make the transfer and then apply it. When printing white or light-coloured shirts, no pre-treatment is needed and as a result the production numbers would be higher with DTG than DTF. That said, at entry level pre-treatment is a separate process for dark shirts, and this is sometimes seen as a negative of DTG as it is an extra step.

Hand Feel

Because you are printing directly onto the fabric, the feel of the print is softer to touch than when a transfer has been applied. No pre-treatment or white ink on light-coloured garments give a perfect hand feel with DTG that cannot be replicated with DTF. At the same time, the cost per print for light DTG is highly competitive.

Fabric Type

At most levels*, DTG printing is perfect for use with cotton or cotton mix garments so polyester, nylon, teamwear, sportwear and workwear has always been more of a challenge. This for me is where DTF really has a place in the market. (* At industrial level, DTG on polyester has been developed)

Sustainability

Because the ink used in DTG is water based and the ink is applied directly to the end garment, it is arguably the most sustainable textile printing method in the market. No excessive ink wastage and no carrier material to be destroyed as we see with vinyl cut and transfers of any type.

DTF Printing

Speed

The same process is used whichever colour or fabric type you want to print onto, so production is consistent throughout and you have the advantage of manufacturing transfers in advance of needing them, so with an ongoing customer for example, the actual production time to print the garment is quicker, if you are producing the transfers on a different day and storing them.

Hand Feel

Arguably worse than DTG as the carrier material, usually plastic, will create a sheen finish to the print, slightly harder to touch. This is an area to investigate though, because as new consumable products are developed this will improve, and as more testing takes place, slower/faster dry times etc can give different results.

Fabric Type

This is a big win for DTF. By making the transfer it can then be applied to pretty much any fabric out there opening up to all garment types and industry sectors.

Sustainability

In a world where marketing is driven by influencers, and we are all becoming more aware of our environment, no-one wants to appear to be un-sustainable and the fact that DTF requires a carrier film, whether it is bio-degradable or not, for me is a big negative of this process.

So, how do you decide on which process your business needs? Is DTG really on the way out? I think not, and I truly believe there is space for both in the future of garment decoration.

Any successful garment decoration business, subject to space and budget, will benefit from having sublimation, transfer, vinyl cut, DTG, DTF and embroidery in their scope of decoration equipment. Each process lends itself to a different type of production and order and having the flexibility to choose which process is right for the job, will help the business grow in terms of profitability and quality of service to the end customer.

I would recommend talking to the suppliers out there, and if you want to venture into this maybe look for a DTG machine, where the RIP software has been adapted to work with DTF production as well. This way you get the best of both worlds.

Also consider your production numbers, space that you must house the equipment, and what is the product / customer you are wanting to serve. If all your business is teamwear then DTF is a must for you. If you are looking at branded fashion t-shirts, then DTG is probably a better solution.

Feel free to contact the Amaya team to talk through your requirements. We will of course be impartial, and as always consider your business and its need first and foremost.

Useful Links & Advice

Kornit Digital | Kornit Direct to Garment Printers

Kornit Digital | Kornit Direct to Fabric Printers

Polyprint | Texjet Direct to Garment Printers

Polyprint | DTF Xpress Consumables

Visit www.amayauk.com or call our team on 02392 590 281 to arrange a visit to our permanent exhibition centres.