How to Cope with Larger DTG print orders!

As your DTG business grows you are faced with big decisions with regard to which printers you purchase. You probably have one or two of the entry-level printers such as Texjet, Brother, DTG or something similar. These printers £10K to £18K and can produce from 80 to 160 prints a day. There is nothing wrong with this type of printer, it is probable the best choice for finding out what the market is about and what level you would like to end up in.

Operating one or two DTG printers can be handled by one person, but then there is the pre-treatment process to consider. As your business grows you could have 10 or more printers and around five pre-treatment machines and 5 heat presses. So, for 10 DTG printers you would require at least 5/6 operators. You are now getting to the point when your production is becoming inefficient with regard to labour, ink costs, production rates and the space taken up by such equipment.

What are the options if you want to make your DTG printing business more profitable, more productive, more efficient and be able to cope with mass personalisation?

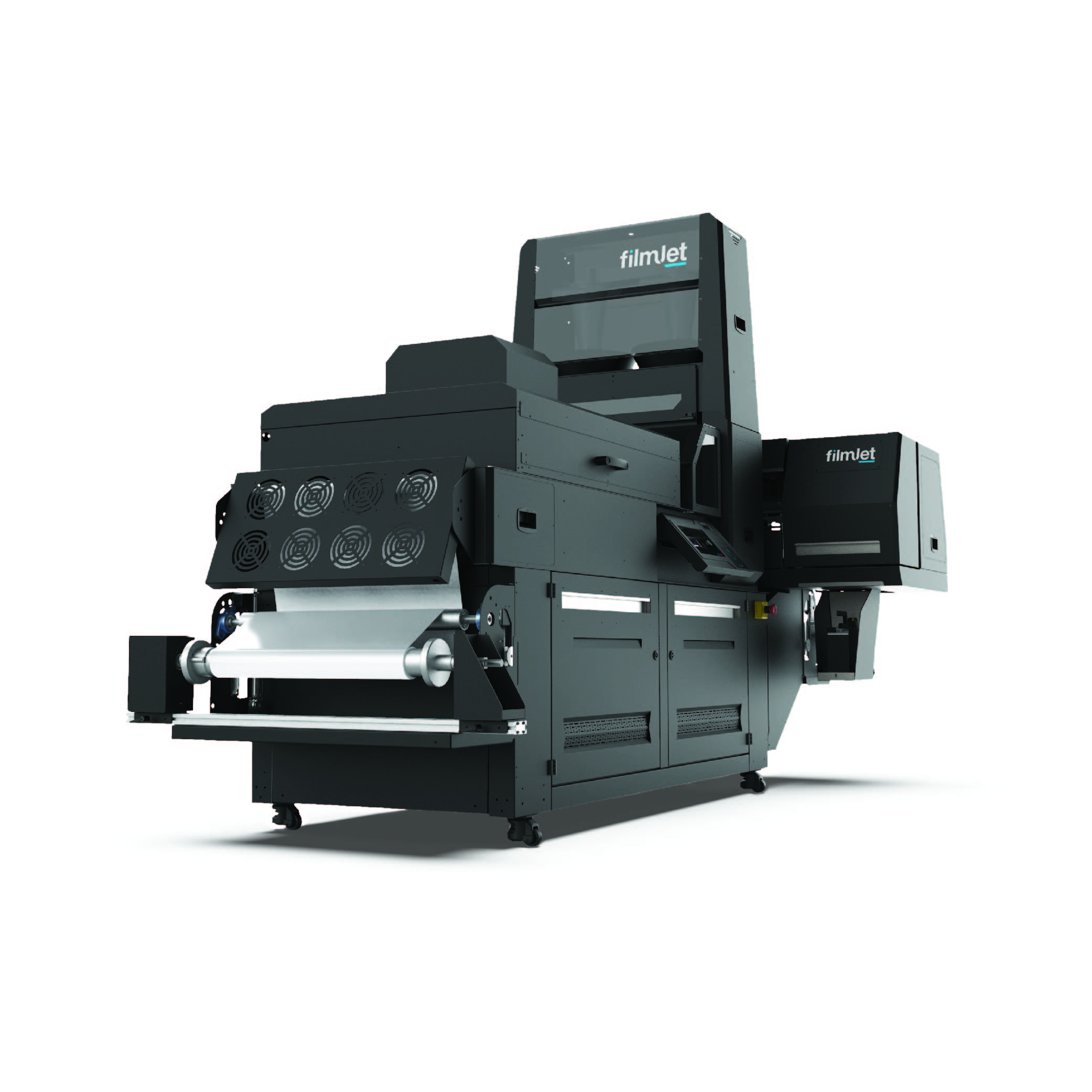

At Amaya, we offer three brands and level of DTG machines, Texjet by Polyprint, Roland and Kornit Digital industrial level DTG printers. The Kornit range can produce from 80 to 160 prints an hour on dark garments. You might think that you cannot afford such a printer but please think again. Ask us to go through the return on investment with you. I promise you that you will be amazed at what you can produce and what you can afford. These industrial printers range from £150k -£600k, but if you have the through put of orders, your ROI on one of these professional printers could be as little as 7 months.

Kornit DTG Printers | Unmatched productivity | Amaya Sales UK (amayauk.com)

With one of these printers you could produce the same as around 10 of the start-up machines, but you would only require one member of staff to operate it and maybe another to offload from the dryer and pack. The process on these industrial printers is made easier because of the built-in pre-coating or fixation system. All the operator has to do is load the design into the Rip software, load the garment onto the machine bed, press print, and then dry on the tunnel dryer. Even the loading of the design can be made simpler by using web to print technology that is now readily available. Designs can be taken straight from a website to the printer operating system.

Another important factor in cost-saving is the very low cost per print that can be achieved using the latest in Neo pigment Eco Rapid ink. Also, the ink carries the Oeko-Tex and GOTS safety certificates, so you confidently supply to all markets from a sustainability perspective.

With the lowering of these costs, the Kornit Industrial DTG printers provide a cost-effective alternative to screen printing for all different sized runs plus allow for one-offs. This comes without the time-consuming set-up of screens and the post-cleaning of them. You can produce screen print quality and hand feel at a fraction of the time and cost. Some of these printers print in CMYKRG and white giving unbelievable colour and clarity.

So, please don’t be put off by the cost of the equipment, look at the numbers you could be printing and then talk to the suppliers. Ask them to work through your return on investment and then make a decision.

The DTG printing industry is growing rapidly year by year, so don’t be left behind, find out more about this highly profitable business.

If you have the demand to print 80+ garments per hour, then book a hands-on working demonstration at our Nottingham office to see for yourself what a Kornit DTG printing solution can produce with just one operator. Bring your own designs and garments to run your production, and learn just how affordable a Kornit DTG system can be.