Direct To Garment and Direct-to-Fabric In an evolving world

Julian Wright – Sales Director at Amaya

Since the COVID-19 outbreak begun, my thoughts look back to working from home completing week one of family isolation amidst screaming children, and a 24-hour news stream. I consider it has never been more apparent than now, that cash is king and liquidity in business is essential.

If you look at successful businesses in the 21st century, who are cash-rich, chances are they are offering a product or service, holding little or no stock, and probably not offering credit.

The spread of the Covid-19 has broadly affected supply chains crippled by quarantine issues, travel restrictions and factories closing. This is causing a significant number of companies to explore more local options now and regretting why they didn’t do it before.

Before the outbreak, manufacturing overseas was already being scrutinised. The model itself generally requires large stock holdings. Large stock holdings require large storage facilities along with a substantial labour force for distribution. The most significant problem is when we have an economic downturn. The stock can’t be sold and turned into cash, but the overheads still exist and cashflow becomes static throughout the supply chain.

The other issue with this model is about consumer choice. We are accustomed to the crash sales that most retailers favour, to clear surplus stock which we the consumer, at full price, just weren’t interested in. Far better to make or print clothing that people have chosen and ideally paid for first …. surely?

The fashion industry itself is a big ship to turn. Historically many brands have benefited from very low production costs, and subsequently very high margins at the retail end, needed to support high retail expenses. Manufacturing locally then doesn’t appear that attractive. So why change?

The reasons are both ethical and financial.

If you consider the wasted money in storage and distribution facilities, the huge amounts of product that have been paid for and are simply not sold (a leading retailer last year reported over $4.3 Billion worth of unsold stock), and then the significantly reduced revenues created by crash sales. These are the financial reasons and this in itself should be enough reason to change.

Then we look at what should be the driving force behind the change – Sustainability!

Have you ever considered the extensive carbon footprint of the clothes you buy and wear? The huge distances they travel to get from the manufacturer to the retailer or e-tailer you purchase from? Not to mention the huge amount of water wastage from traditional printing and dyeing methods. That’s ethical.

For most, clothing is a way to express yourself, to differentiate you from the masses.

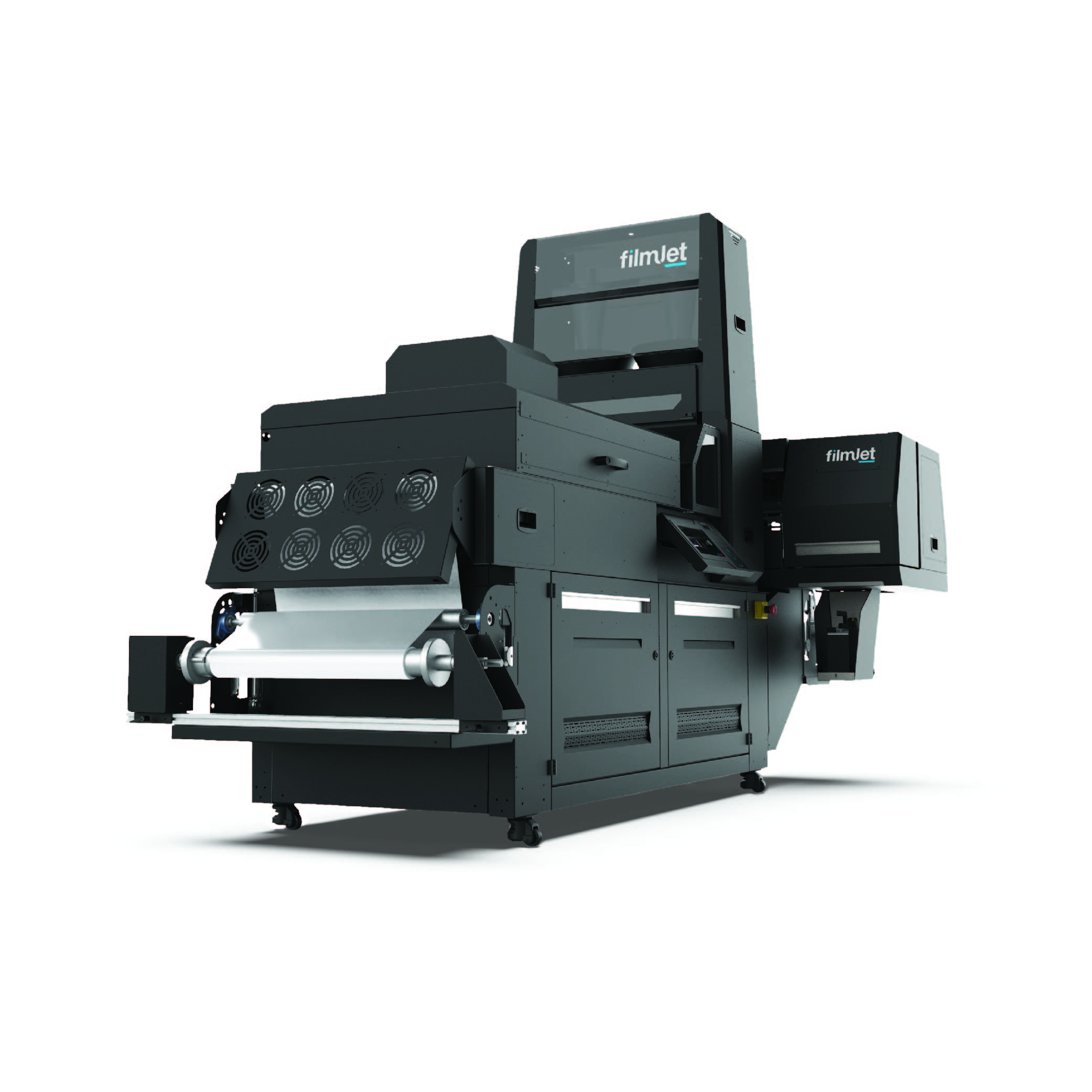

DTG (Direct to Garment) and DTF (Direct to Fabric), enable brands to give their customers just what they want and quickly, whilst at the same time making good ethical and financial choices as an entity.

It is no surprise then that smaller independent brands have gathered a huge amount of pace in recent years, and for those that utilise the massive potential of DTG & DTF, you can guarantee they are not sat on surplus stock. They simply print what the customer orders and take payment before a single drop of ink leaves the print head. Their business investment is capital upfront, and as they manage their ranges minimum blank stock waiting to be customised, with a small workforce capable of producing 100’s of prints per hour.

I have worked with many start-up brands and businesses over the years, selling them their first DTG printer and watched as their ideas and drive have blossomed into serious business entities. They didn’t need convincing that digital was the way to go, because they didn’t know any differently, and didn’t realise they were making better choices than some of the brands and business models that they aspired to.

Capital cost is a big concern of people when thinking about DTG and DTF, particularly on an industrial level. But with interest rates at an all-time low and the right brands holding their used value, spread over 5 years it’s an expense many companies can afford, particularly with reduced labour costs.

So, as 2020/2021 has made us all reflect more than ever, consider Direct to Garment and Direct to Fabric printers for your business.

It makes financial sense, which makes business model sense, and most importantly it makes sustainable sense!

Please call me and let me explain all the benefits of our Kornit Digital DTG and DTF (roll to roll) systems. I’m sure you will be surprised when we work out your return on investment.