The Growth of DTG Fulfilment Centres in Garment Printing

DTG printing has grown rapidly over the last few years, mainly because of the feel, photo-realistic quality and low-cost set-up compared with screen-print. On the back of this, the amount of fulfilment centres is growing. These range from small companies with a few DTG printers, right up to very large companies that have invested heavily in industrial DTG equipment that will give rapid production and top-class quality.

What is a fulfilment company?

A fulfilment company will print, pack and drop ship your garments directly to the end-user. For example, if you design t-shirts, you would create your design, send it to the fulfilment company and they would take care of the rest. It would then be sent under your own label directly to your customer. This would leave you to get on with the creative side of your business and be rest assured that your product will be delivered on time and printed to the highest quality by experts.

You don’t have to worry about stock because the fulfilment company take care of that. You don’t have to purchase DTG printing equipment, again the fulfilment company take care of that. So, if you are setting up a new brand, launching a shop on a social media platform or just designing t-shirts, fulfilment is the easy way to distribute your goods.

Sustainability

Kornit Digital has developed an ink that is specifically designed for sustainability. Their water-based NeoPigment inks are 100% non-hazardous, toxin-free and adhere to the strictest human health and environmental standards. It complies with Oeko-Tex 100 for infant wear, GOTS-3V, RSL and AATCC standards. It contains no animal by-products and is completely vegan friendly.

The above sustainability allows the fulfilment companies with this equipment to supply all types of business without restrictions.

Web to Print

Apparel e-commerce and online shopping are growing rapidly, serving customers need for variety, personalisation and self-expression. The traditional supply chain is changing from supply and demand, to demand and supply. Many of the fulfilment companies have a web to print solution that will speed up your order flow, giving seamless integration and offering your customers exactly what they need.

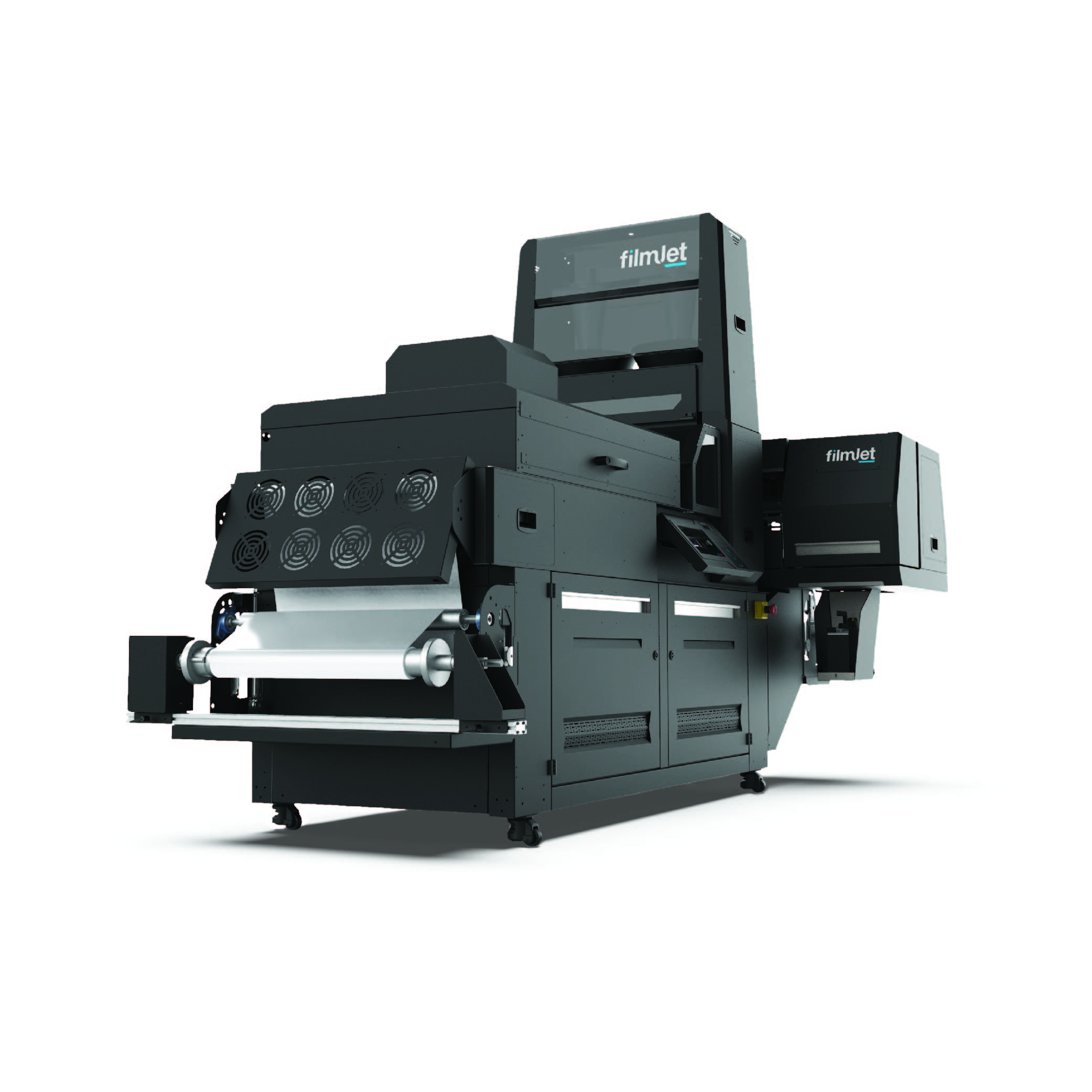

Industrial DTG Printing Equipment

For the fulfilment centres to offer their customers the best in service, they will need to invest in the best equipment for the job. The top companies are spending upwards of £500,000 on purchasing Kornit Digital DTG solutions that gives them both the speed, and the quality to satisfy their customers and themselves. They need equipment that brings the cost of ink down to a level that makes the business viable for both parties.

Another benefit of this equipment is that they have built-in pre-treatment, this cuts down drastically on process time and labour. The process is simple, just load your design, load your shirt, and then dry through a tunnel dryer. Although these industrial printers seem expensive, if you have the business to put through them, the return on investment is excellent. One operator can produce around 700 printed shirts a day on an 8-hour shift. With the smaller systems which produce around 150 -200 shirts a day, they would require probably 3 or 4 operators on 4 printers. So, add the saving on labour, production time and the much-reduced cost of print (can be as little as 50p on A3 design), buying the right industrial DTG printer is essential for a cost-effective fulfilment business.

So, whichever side you are on, fulfilment centres are a very important part of the DTG business. Some companies will use them in the beginning whilst they are deciding whether to buy their own DTG printers, others just want to give the work out and concentrate on other sides of their business.

DTG Printer | Integrated Pre-Treat | Kornit Digital | Amaya Sales UK (amayauk.com)

At Amaya we offer Kornit Digital Industrial DTG and DTF printers. Speak with Julian Wright on 02392 590281.