Are you confused about thinking of which DTG printer to buy?

I should imagine that many of you have visited Printwear & Promotion LIVE!. At the show there were many different makes and sizes, with prices ranging from around £7,500 up to over £450,000. So, which is the correct fit for you and your company?

Pricing

Pricing at the show seemed a bit erratic, some dealers dropped their prices significantly, by has much as 35% and others by the normal show discounts of between 7.5% and 10%. I would personally be aware of suppliers discounting by 35%. How can they afford to do this, I ask myself? Either they are about to launch a new printer, or their printers were massively overpriced in the first place. The other thing to consider is if you had purchased a printer at the normal price, your asset is now worth more than 35% less. Suppliers need to make a reasonable margin so they can exist and offer you the kind of support you would expect.

Print area

Decide what printing area you think you will require and what market you are going to sell into. Printing areas range from 32x45cm through 41x60cm up 42x95cm. You can also find multiple platen configurations for higher productions but obviously the pricing for these would be higher. I would always go for something in the middle, like 41x60cm so you have the flexibility to print full size on a T shirt, remember, you can always print smaller than this. If you know that around 32x45cm will satisfy your customers, then you will save yourself at least £3,000 in equipment cost. The market you are selling into will define what maximum size printer you require.

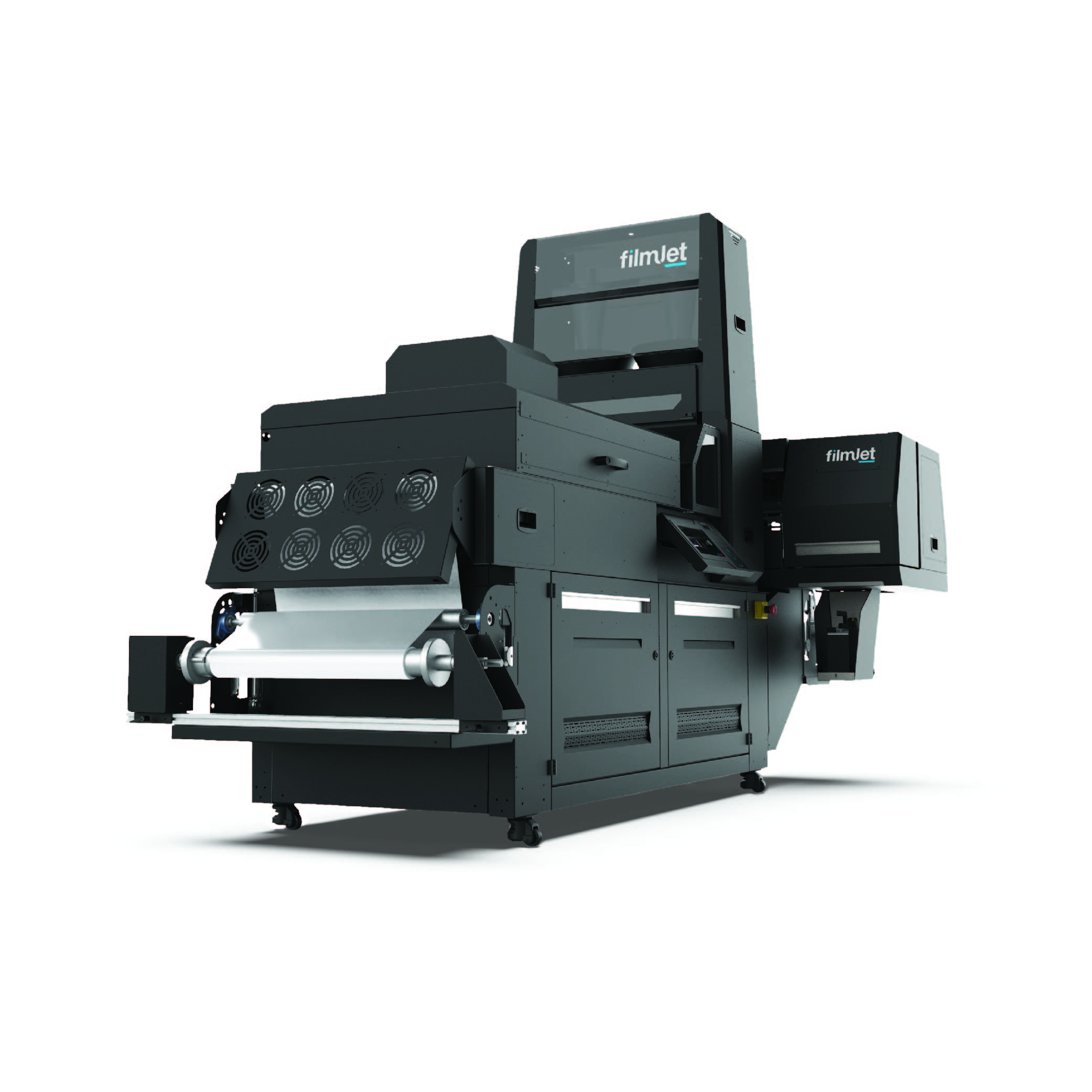

Modular

Some printers are modular, which means you can have more than one printer connected to one PC and RIP software. This could be an alternative to paying out for one larger and more expensive one, buy three or four around the £10,000 mark each. This is a big advantage if your more expensive printer breaks down, if you had modular ones only one would be out of action.

Big mistake

One big mistake when buying a DTG printer is not to check the ink and maintenance costs. The cost of inks on printers with sealed cartridges is nearly double the cost of re-fillable cartridges. These suppliers will try and hide this from you or tell you that sealed cartridges are a must. If you are using your printer every day, the best buy would be a printer with a pressurised ink system and re-fillable cartridges. If you use the printer one or two days a week then sealed cartridges are preferable. Look carefully at the warranty conditions of DTG printers, some systems have to be flushed out around every month and have certain parts changed to comply with its warranty. Flushing a system out and changing parts could cost you another£150-£200 a month. Add this to higher ink costs and you have more or less doubled the monthly cost of the printer. So do your homework and choose wisely.

Production

Most printers in the £7,500 to £15,000 bracket will produce around 10 to 20 per hour on dark garments and double that amount on whites. This is obviously dependant on the size of print. There are more expensive printers out there, ranging from £60,000 to £500,000 that will give very high production figures, these are more suited to companies requiring around 100 prints per hour.

Support

Whatever level of printer you decide on, the most important question to the supplier is, what sort of support do you offer.

The problem with this question is that all suppliers will say they offer superb support. So, I am afraid it is up to you to find out for yourself.

There are several ways of doing this, you could ask your supplier for referrals or look on forums (make sure they are recent entries and relate to the UK). Ask how long they have been selling and supporting DTG equipment, how many engineers they have on the road, are they their own personnel or freelance, have the engineers been factory trained.

At Amaya we offer both entry level (Polyprint Texjet) and fully industrial (Kornit)

Book your demo experience today, contact our team on 02392 590 281