Don’t Overlook DTG Printing

Why it remains a valuable option amidst the DTF hype

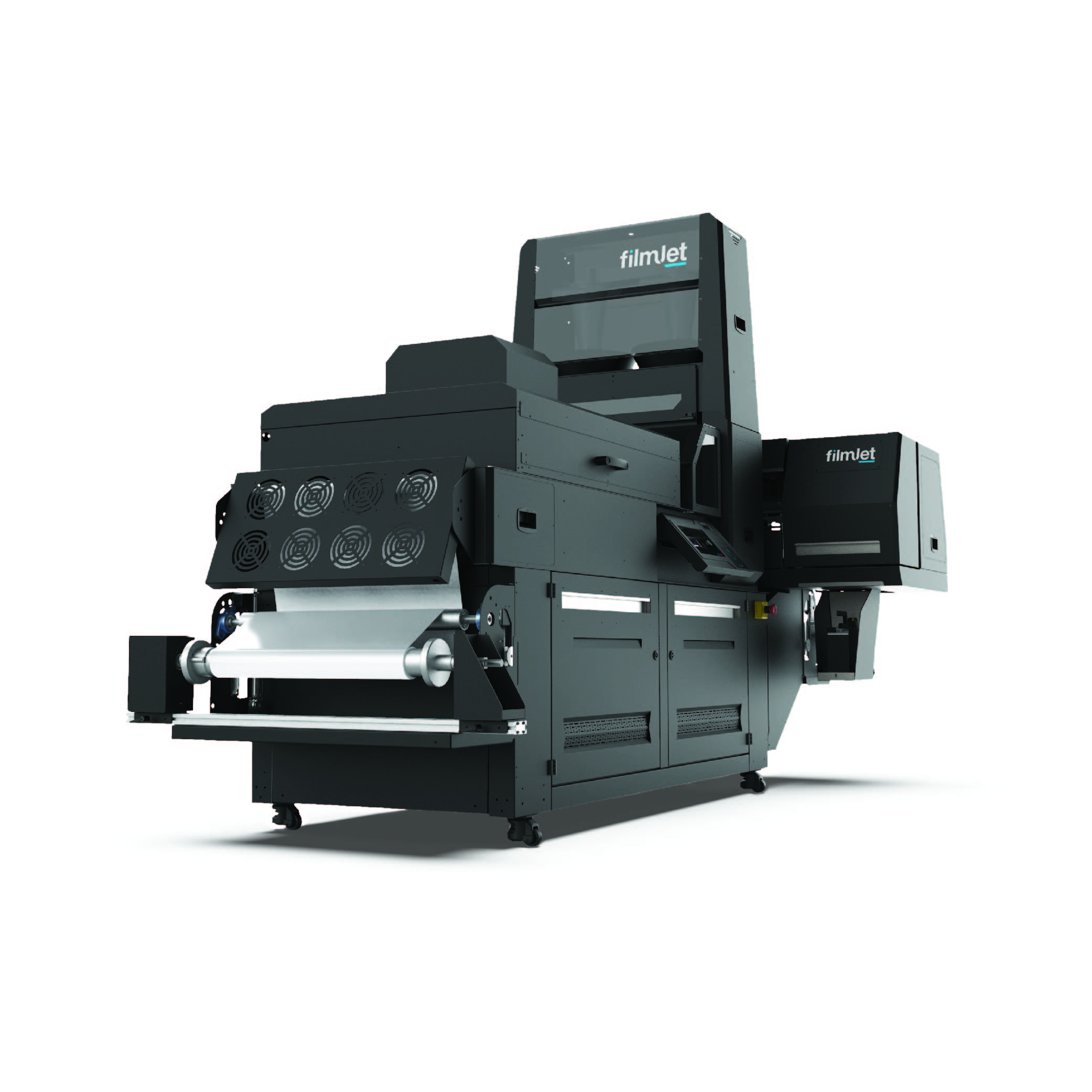

In the last couple of years our industry has been flooded with a surge of interest in Direct-to-Film (DTF) printing touted for its versatility and cost effectiveness. Well established garment decoration names have taken various options of equipment into their portfolio and many new names have come to the market.

DTF has gained momentum due to its ability to print vibrant designs, at a low cost onto a variety of substrates including cotton, polyester, nylon, and blends. It has allowed many businesses to bring affordable and efficient transfer production in-house.

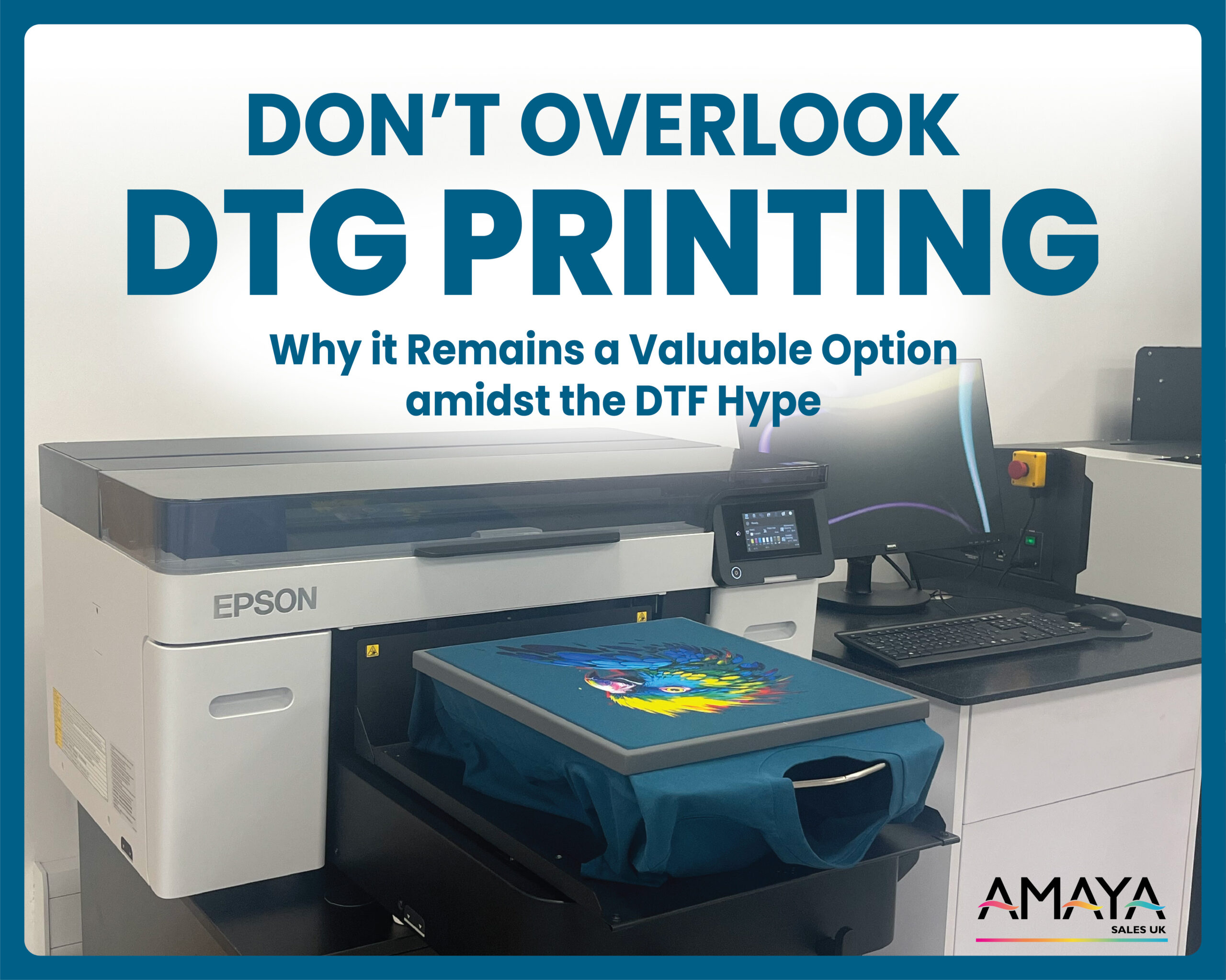

However, at Amaya we believe it’s really important not to lose sight of the best solution for your production and your customer. We think everyone should consider the benefits of the more established digital process Direct to Garment (DTG) Printing to work alongside DTF.

Quality – DTG printing is renowned for its exceptional print quality. By directly printing the design onto the garment DTG technology will achieve a soft hand feel and tackle small fine writing and artwork far better than a DTF transfer.

Durability – This is a big one as a DTG printed garment will withstand multiple washes without fading or cracking, making it more suitable for high-quality apparel and merchandise and a preferred choice for the larger retailers and brands.

On-Demand Production – in today’s fast paced market DTG printing enables on-demand production better than any other process. With industrial systems printing around 140 shirts per hour from start to finish with one operator, there is no faster more efficient way to decorate apparel and it is the reason that the big fulfilment printers are using more DTG than DTF.

Cost-Effectiveness – here you need to consider “real cost” not just ink and consumables. Yes, a DTF transfer when produced in bulk, let’s say for a 100-shirt order may be in some cases cheaper in ink and film than pre-treatment and ink, however two scenarios to consider:

a) Factor in the time it takes to print & powder with DTF and then the labour to cut, sort, and apply with a heat press, and then re-seal, and then compare shirt by shirt with DTG. You’ll be surprised at your “real cost.”

b) Consider you have an order for just one t shirt. Customer wants it now, print it in a few minutes with DTG and your cost is just the time and inks. Print it on DTF and you will need to set your machine up, run some film through and then print just one image, so your film and powder are significantly more than that used for the one shirt order.

Sustainability – DTG is by far the most eco-friendly garment decoration process available. Unlike traditional screen-printing that requires extensive set up, use of chemicals and excessive waste, or DTF transfers which are printed on a PU non-recyclable film, DTG printing with its water-based inks and solutions minimises environmental impact. With climate change affecting us all, this is huge consideration for environmentally conscious businesses and consumers alike.

DTF is a necessity for polyester, nylon and other non-cotton based fabrics, and is great for difficult to print areas on a t shirt, like back necks or sleeve and truly compliments DTG and in some cases screen print.

There is no one process that suits all garment decoration production. At Amaya we say DTF and DTG should work in harmony together, to give your business the best chance of success.

Explore our selection of DTG printers by clicking here.