Transfer Print – The Low-Cost Way of Printing Full Colour

Easy to use, soft handle, great durability and cost-effective – all of these things would not have been associated with heat transfer papers in the past. However, as laser printer technology has become more advanced over the years, it has allowed a new breed of transfer papers which break the mould of those earlier papers.

It all started with printing on to white, light and pale garments. That said there were some early transfer papers available for dark garments, but it was hit and miss as to washability and handle.

Then, out of nowhere and it felt like almost overnight, Oki introduced the white toner printer range of LED laser printers and it changed the industry. Today the Oki Pro7411WT, Oki Pro8432WT and OKI Pro9541WT are a must-have for any size of business in the garment decoration sector of the market.

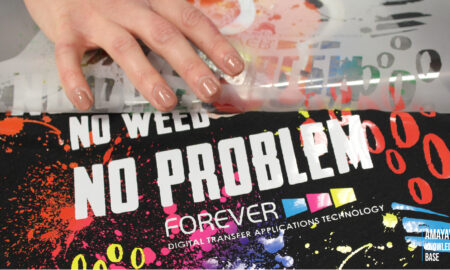

These printers allowed the production of the no weed, no cut full-colour logos onto light and dark garments, whatever the fabric.

Use the Forever transfer paper and you have a perfect match for creating full and single colour quality prints.

Gone are the days of having to weed out, manually cut or trim your transfer paper and then heat press it to a garment. This means that the speed of producing full-colour transfers is now much quicker and more accurate, so order quantities can be much higher, and it’s still cost-effective for the end-user. Less time weeding also means that many man-hours are saved in production, so everyone wins all-round –operator and customer.

Simple changes

It is so simple. Print your image onto the A foil paper, heat apply the B paper – adhesive/opaque backing and you are ready. No lining up issues, no small detail issues just ready to use full-colour transfers.

The Forever Dark No-Cut paper has now, indirectly, introduced no limits to its title along with a flurry of similar products in the range with the use of the white toner printer. This technology was also used to create a single colour transfer that did not need the expense of the white toner printer. Using a standard CMYK or black laser printer with Forever Flexsoft transfer papers you can produce intricate designs in metallics, neon’s and standard colours. And again, with the no weed, no cut advantages.

Using these lower-cost printers allows a lower entry cost into the T-shirt printing industry. Many new businesses have started at this level and upgraded to the Oki white toner printer to produce full colour on to dark products at a later stage.

Big advantages

Another big advantage of the Forever Transfer Papers is that these transfer papers have a wide spectrum of heat press times and temperatures. You can now use a variety of different heat presses and are not forced to use one type of press. If you have a good heat press – clam, swing or pneumatic and they have good heat distribution then you could use the Forever Transfer Papers successfully.

You can now use the same transfer to adhere to white, black or anything between in colour, cotton, polyester, poly/cotton, nylon, lycra and more by just altering your pressing technique according to the garment being pressed onto. Depending on what printer you have, means that you could utilise one or all of the full colour, single colour, neon or metallic finishes – in gloss or matt!

Finally, Forever offer a transfer Rip that controls your cost of toners and allows you to rasterise images. Rasterisation gives you a design with a better feel, better washability and great colour.

As well as the garment laser heat transfer papers there is also a range for hard surfaces, allowing you to print on ceramics, slate, wood, leather, etc. in full colour, single colour and metallic finishes.

If you have stayed away from this process in the past – now would be a good time to take another look into the laser heat transfer systems and consider adding it to your range of garment decoration processes. I am confident you will be pleasantly surprised.