Supercharge your Embroidery Production and make more profit.

Your embroidery production can be affected in so many ways. Avoiding some or all of these can make a massive difference to your output and profitability. Here are some tips that can help you improve your current embroidery production.

1. Machine Maintenance

Machine downtime can cost you thousands of pounds of lost production and profit. If production is slow you stand to lose customers by not completing your orders on time as well.

Embroidery machines are probably one of the most expensive parts of your business but many of them are neglected with regard to service and settings. Please make sure your machines are regularly maintained up to the manufacturer’s specifications.

Most of this you should be able to do yourself, but I would advise on having a trained engineer from the supplier at least once a year. You may think that the cost of a service is expensive but compared to any loss of production it is negligible. Call your supplier for a quote now.

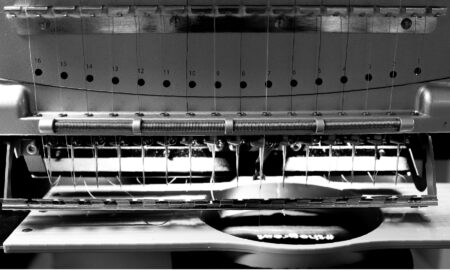

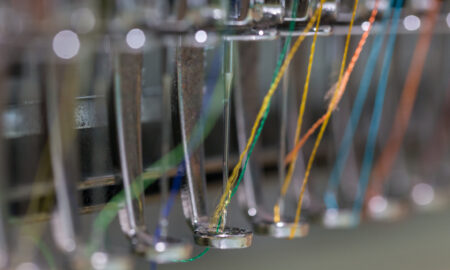

2. Thread Breaks

These are the most common cause of machine downtime. If they are happening on a regular basis it is very important to find the cause. A machine in good working order should have very few thread breaks. Things to check:

- Check the condition of the needle and its positioning.

- Check the thread tension.

- Check the bobbin tension.

- Check the thread path is correct.

- Check the condition of the thread.

Old thread (especially Rayon) can also cause problems. With fixed multi-head machines the worse thing is a thread break will stop all your heads producing – one break can stop production on six garments. However, with a modular system like the Melco EMT16’s one thread break will only stop the head it is broken on – the rest of your heads will continue to run – so much more efficient.

3. Framing

Optimum production is achieved by preparation. Once one garment is running on your machine, get the next one framed so as soon as the design finishes it’s ready to pop on. Have at least two sets of frames per size per machine so the machine is only standing still for seconds.

Also, make sure you are using the right frame for the job. Consider special framing systems to help you speed up framing or make it easier for your embroidery operator.

The Hoopmaster system is a great way to make framing easy and accurate on every garment throughout an order.

Think about magnetic frames for difficult to frame fabrics – heavy fleeces, leather and wool can be hard to frame which costs you time, as do difficult shaped items like belts, straps and shoes, for this try the Melco Fast Clamp system – a saviour in many embroidery departments.

Finally, with framing, make sure you have the right number of operators to match the number of embroidery heads you are running. One person less than required can cause heads to be left ideal when garments are finished or bobbin changes needed.

Another big benefit of the Melco EMT16 modular system is as heads finish and you change the garment the head will start running again without waiting for all heads to be changed. on a traditional multi-head, all heads will finish at the same time and production won’t start until you have re-positioned all garments.

4. Optimise your work area

Make sure your goods in, goods out and framing area are adjacent to your machinery and you have a good workflow without obstructions.

5. Digitised design

Test run your new designs on the fabric you want to embroider them onto, not just felt, to make sure they run free of thread breaks and do not contain too many stitches. Stitches on top of each other and a heavy density can cause thread breaks and downtime.

6. Design input

Make sure that new jobs/designs are in place to minimise downtime. Some machine systems now have a barcode system that will enter information from the worksheet directly into the machine.

7. Modular embroidery system

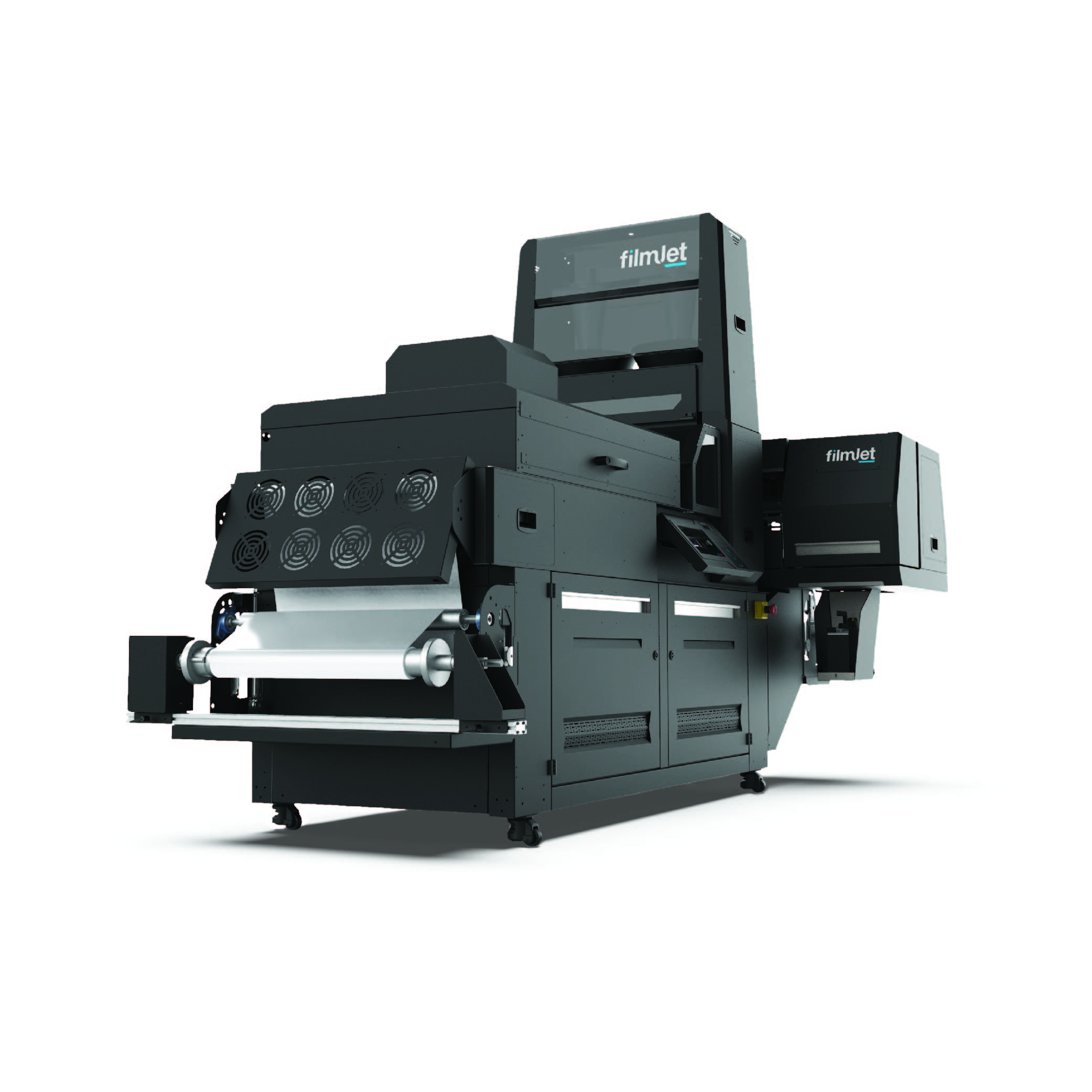

I’ve mentioned it above but if you are running conventional multi-head machines you really should consider a modular embroidery system. The Melco EMT16X’s are the only machines on the market that are truly modular. A series of machines linked by a PC with operating software that allows you to control them all from one point. A modular system gives you the flexibility of:

- Each head running all the same design or each head running a different design. This gives the flexibility of orders – you can be sampling on one and running 4 heads on another order. Or running different personalisation on every head.

- The auto-tensioning that comes on the machine will save hours in preparing your machines for different fabrics.

- Less downtime for thread breaks, bobbin changes, garment changes, makes it a far more efficient system.

- Fast and easy changing of garments – as soon as one is re-framed the machine starts embroidering again – it doesn’t wait for the rest of the heads.

Just take a few minutes to look at your set up and see if you can make any changes. You’ll be surprised by the bad habits we all get into – review and improve for optimum production?