How to profit from cap embroidery

I can imagine that many of you would disagree with this. Especially if you have been embroidering for over 10 years and have experienced some of the original cap frame systems. The good news is that cap frame design has changed dramatically for the better.

In the early days cap frames seemed to be an after thought when manufacturers were designing their embroidery machines. A lack of grip and inconsistent movement gave poor registration and quality issues. It was also difficult to frame the caps accurately.

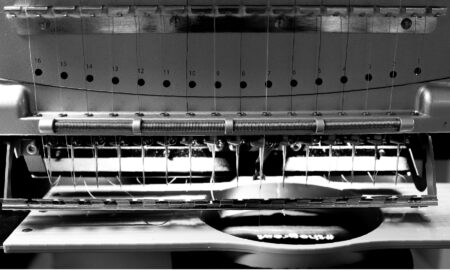

Over the last few years, some manufacturers have put more effort into producing a cap frame that is capable of holding a cap firmly and that is built strong enough to withstand constant production at speeds of 800 stitches per minute and more. At least one manufacturer has employed a specialist engineer to develop what they believe is the best frame available. They can now run their machines at 1,200 stitches per minute and at the same time produce accurate and high-quality embroidery.

So now, assuming you have up-to-date and appropriate equipment, you should be making good money from the lucrative cap business.

Tips for making sure you can produce for profit

1) Make sure you have the best embroidery machine and cap frame available. If you are about to purchase a new machine, ask the supplier to demonstrate cap embroidery. The machine should be able to run at 1,200 stitches per minute while still giving perfect quality. Check how easy it is to change from normal embroidery to caps and how easy it is to frame them up. Make sure the frame holds the cap firmly in place.

2) Buy your caps from a reputable supplier that can advise you on the best caps for embroidery. Some suppliers offer the common six panel cap but with flat front which takes away the front seam problem. Ask for a selection of the caps they recommend and test them on your machine. Then offer your customers the ones that work best.

3) Buy a 270⁰ cap frame so that you can embroider around the side of the cap. Some embroiderers have steered away from doing this, but it could be the difference between your company and the competitors.

4) The embroidery size that your cap frame will allow is also very important. The larger you can embroider your design; the better quality will be achieved and the more prominent the design will be. I believe the largest frame out there is 362x82cm or 14.25×3.23in.

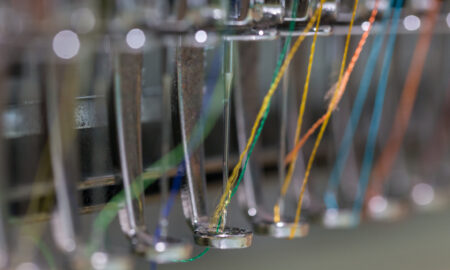

5) Digitising for caps was once very important, but now with the improved cap frames it is less important. In the past it was best to work from the centre out but if the frame holds the cap firmer then this is not necessary. The main thing to remember is that the design on a cap will normally be much smaller than say a breast pocket size. This means that you should watch the size of lettering and small detail.

6) Puff or embossed embroidery is now very popular on caps and can add considerably to you margin and selling price. This process is very easy to create so please ask your supplier for instructions.

So, forget all the negatives of past cap embroidery and get out there and quote for some business on caps. It really is quite easy now and the profit margins can be excellent.

Check out the Melco cap frames at www.amayauk.com or call Amaya on 02392 590281 for a demonstration.