Talk to an expert

For more information or to request a Brochure, call us on 02392 590 281

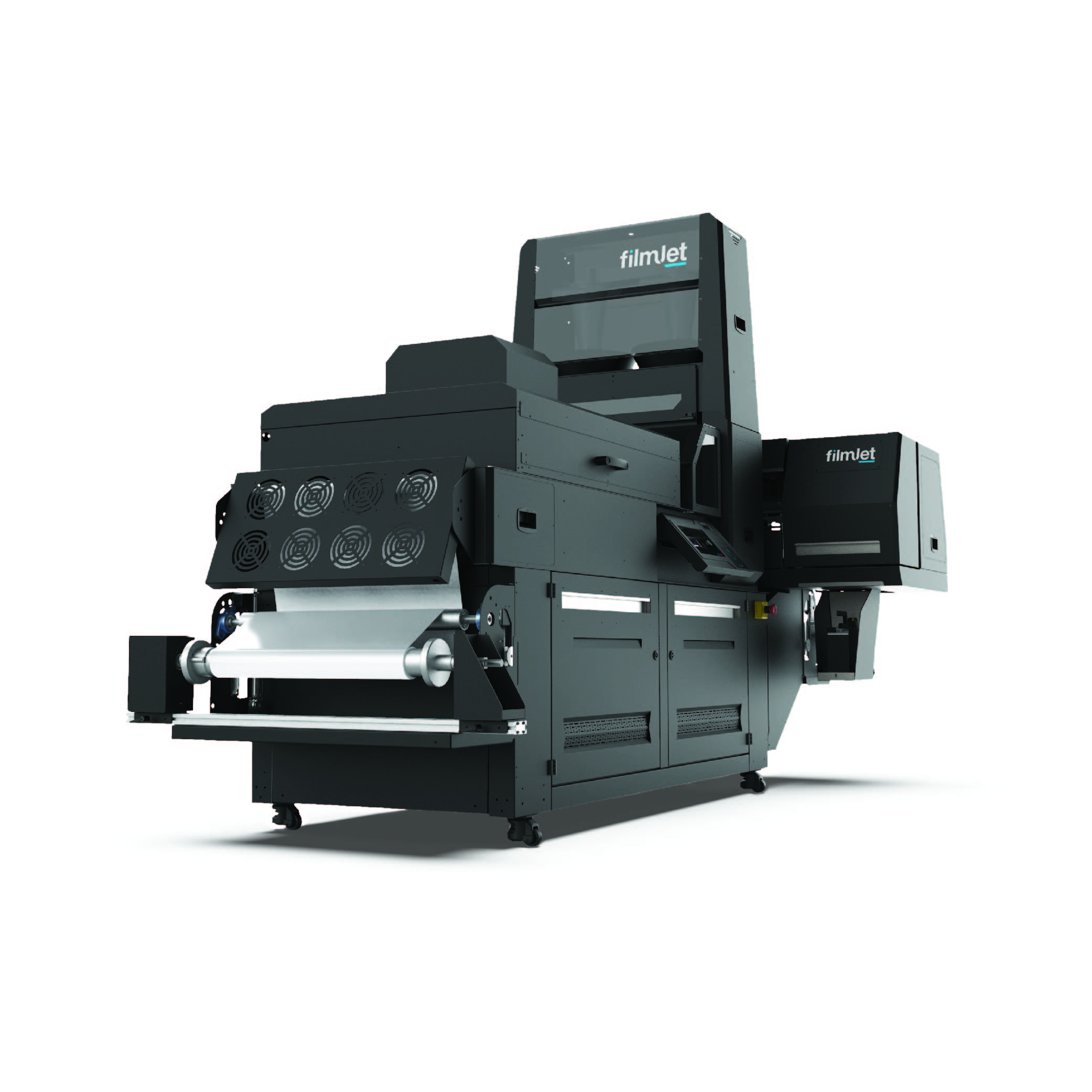

Dryer Ace 600

The perfect match with the Kornit Breeze DTG Printer.

Single Belt From £11,500+VAT

Double Belt From £12,000+VAT

Spread your payments with our Leasing and Finance facilities.

Notice: Most inks, toners and consumables have expiry dates, please bear this in mind if ordering in bulk!

Forever transfers papers are only suitable for use with LASER PRINTERS.

- Description

- Specifications

Description

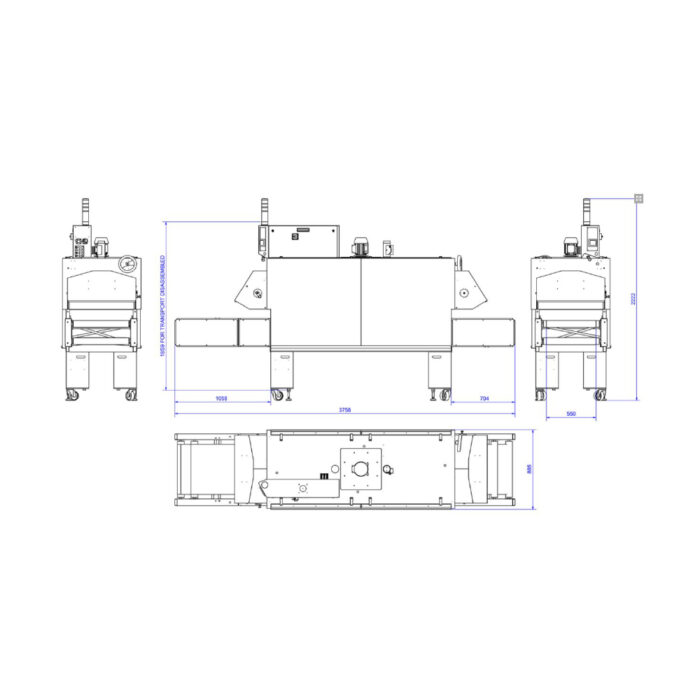

Electric Modular Dryer Forced Hot Air System

The Tetris gamma is a new generation of dryers, built and designed with almost 40 years of experience for long-lasting and high-quality machines, proudly produced in Italy. The latest Lcd control panel has an easy and interactive interface design: time and temperature control are both processed digitally for precise and fast adjustments; the automatic cooling off and shutdown can be set to suit different working necessities; dryer internal technical parameters are also displayed. The entire machine is protected with circuit breakers and thermostats to prevent electrical and heating failures: the digital control panel has also a detailed alarm history chart to improve the safety and maintenance for extended working periods. The Dryer Ace 600 is the perfect match with the Kornit Breeze, which has an output of up to 32 light and 25 dark garments per hour.

ACE 600 PRODUCTION DATA: Water-based Digital Ink – A4 print size on T-shirt – Data may change according to the fabric material, drying area size, and ink curing requirements.

Curing Area: 2000×1200 mm

3 minutes curing time: 100 pieces/h

4 minutes curing time: 70 pieces/h

5 minutes curing time: 60 pieces/h

6 minutes curing time: 50 pieces/h

Features:

- Specifically designed to cure and dry digital printing on fabrics, the massive advantage of these dryers is the high volume of forced air circulation: this facilitates and accelerates the evaporation of water-based digital inks with unmatched results on the finished garment in a medium-long drying process.

- In the heating chamber the temperature is uniform and constant on both sides and the centre, adjusted by a precise thermostat and by a long-lasting static relay control system; in this manner the temperature never exceeds the set value, preventing damage even to the most delicate fabrics. The air exchange is adjusted to discharge steam and promote high volume air circulation. This enhanced airflow convection system is designed on purpose and employs high yield low noise reverse blades. Outflow nozzles direct the air onto the product perpendicularly and at high speed. Filters on each blower fan achieve an efficient and low maintenance working process.

- Heavily insulated mineral-wool fiber structure results in a cooler workplace and cool to the touch external skin. Remarkably it reduces both power consumption and heat dissipation.

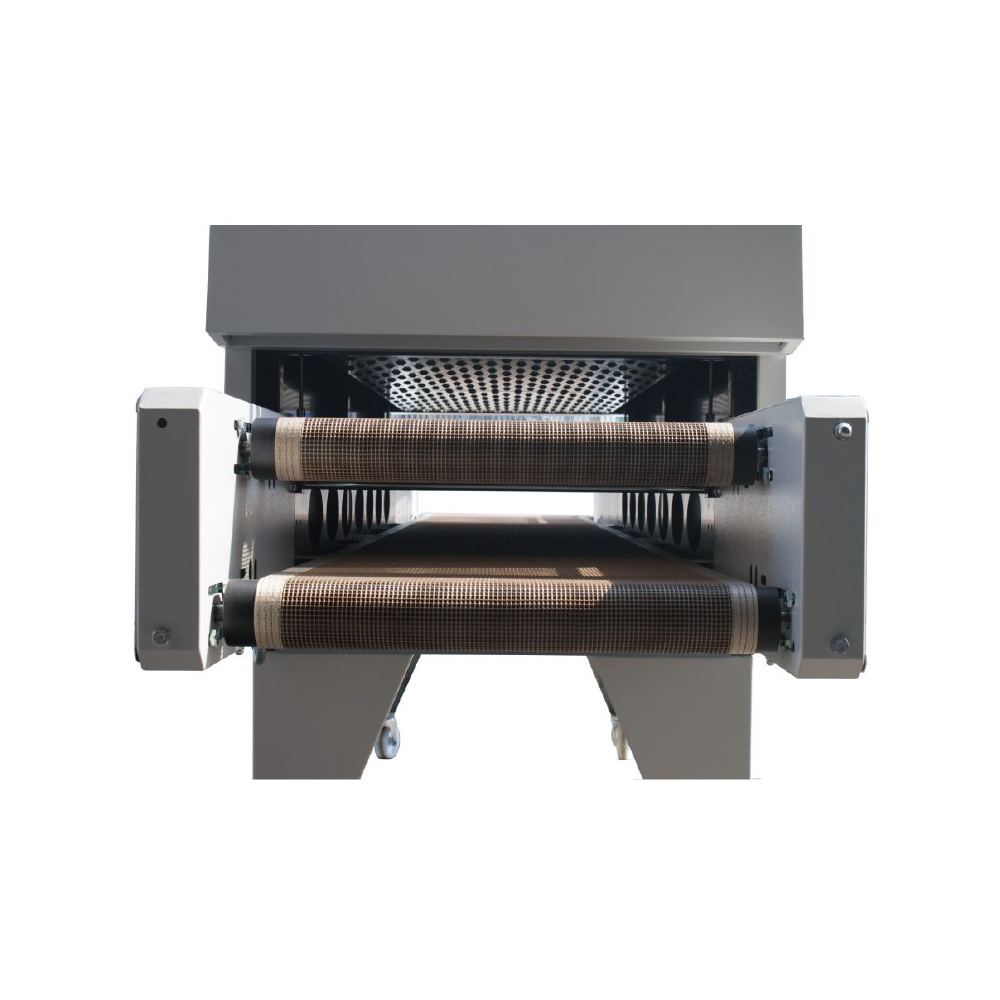

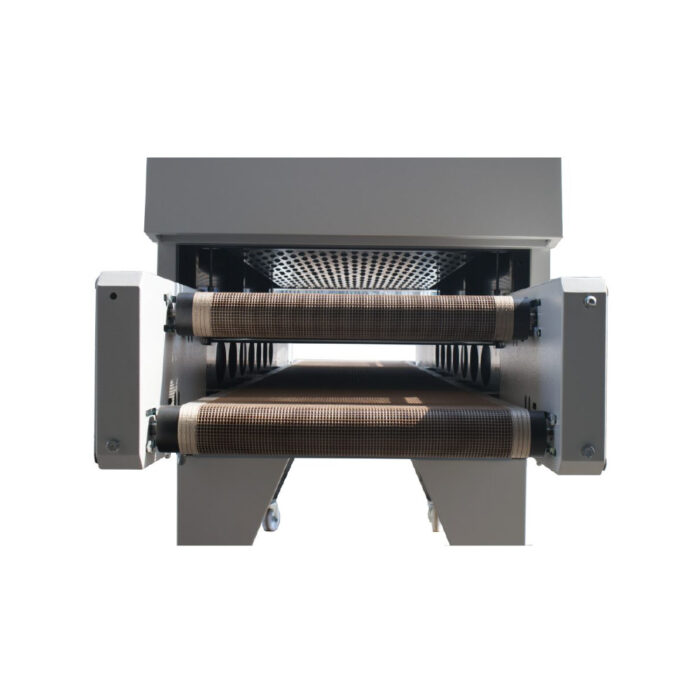

- The returning belt conveyor allows the operator to work without having to change his position; the belt conveyor below works at lower temperatures of about 10-15°C: this improves curing quality and at the same time allows the operator to touch the printed garment without burning risk.

- The double belt conveyor configuration allows operating simultaneously with two independent curing time. Each belt has its own speed control to be adjusted in relation to the ink or garment need.

- The Optional Cooling Hood at the outfeed of the Dryer is an effective cooling system to protect both the operator and delicate products from high temperatures after the drying process has ended.

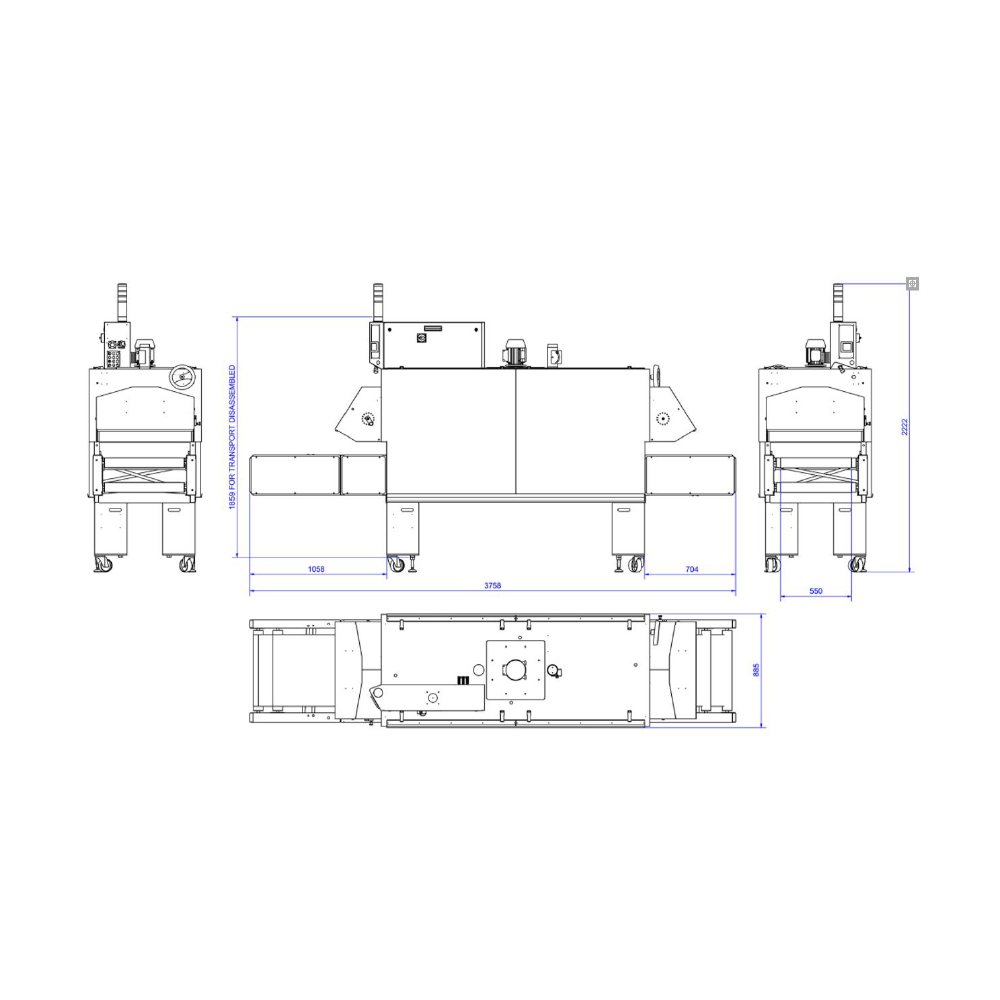

| ELECTRICAL REQUIREMENTS | 400V 3P+PE |

| CURRENT | 15 A |

| POWER (Max) | 9.5 kW |

| DRYNG AREA | 2000 x 600 mm |

| WORKING TEMPERATURE (Max) | 200°C |

| DIMENSIONS (depth x width x height) | 3758 x 885 x 2222 mm |

| EXHAUST FUMES SPECIFICATION | 130 m³/h Ø 80 mm |

| WEIGHT | 440 kg |

Recently Viewed

For more information or to request a Brochure, call us on 02392 590 281