Talk to an expert

For more information or to request a Brochure, call us on 02392 590 281

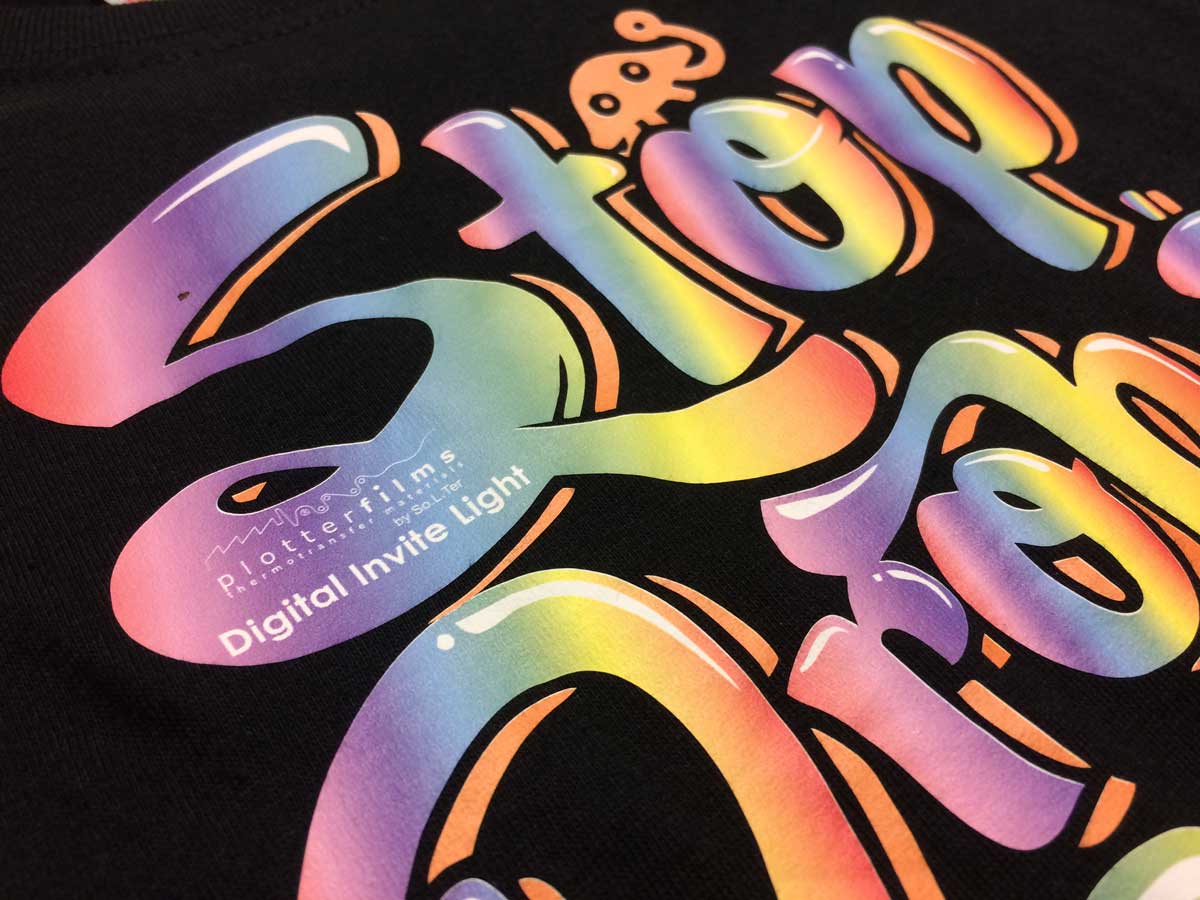

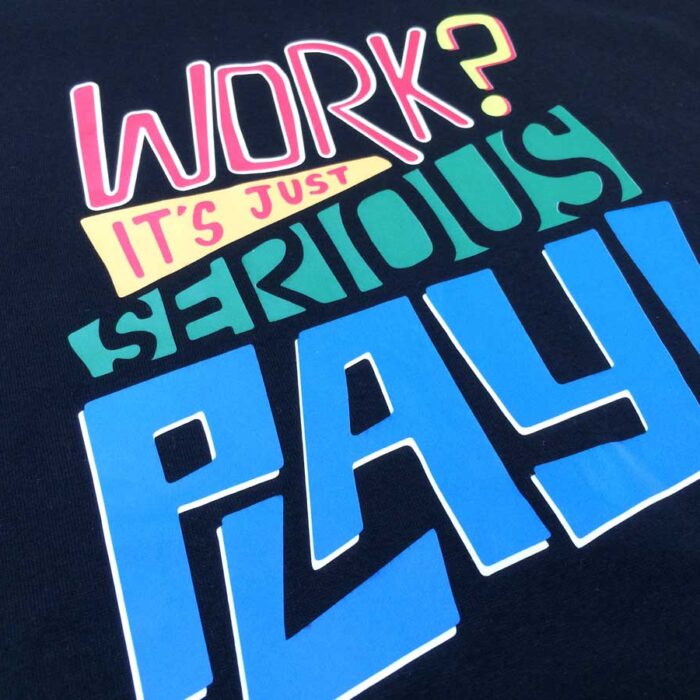

Digital Invite Light – Print & Cut HTV

From: £118.75 +VAT (£142.50 inc VAT)

Digital Invite Light from Plotter Films is a professional-grade printable heat transfer vinyl engineered for high-volume production and intricate designs. This mixed PU/COPES film combines exceptional detail capability with user-friendly application, making it the go-to choice for custom apparel businesses and print shops.

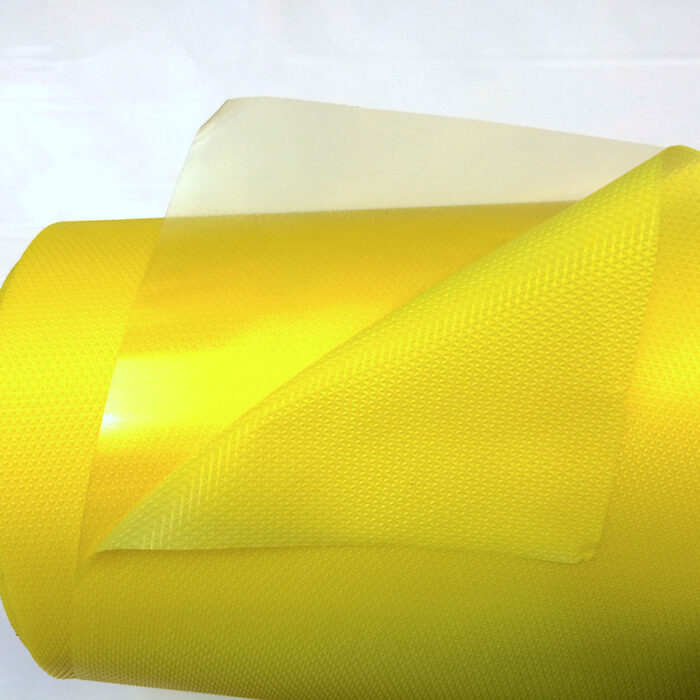

Available in 50cm x 25m or 75cm x 25m rolls.

To be paired with the Yellow Application Tape

- Description

- Specifications

- Application Instructions

Description

Premium printable heat transfer vinyl with adhesive carrier – designed for fast workflows and large production runs

Digital Invite Light is a professional-grade printable heat transfer vinyl engineered for high-volume production and intricate designs. This mixed PU/COPES film combines exceptional detail capability with user-friendly application, making it the go-to choice for custom apparel businesses and print shops.

Compatible with eco-solvent and solvent printing systems, Digital Invite Light delivers vibrant, accurate colours with excellent ink adhesion. This vinyl is optimised for popular Roland printers including the Roland BN2-20, BN2-30, SG3-540, VG3-540 or VG3-640 models, but works equally well with comparable eco-solvent and solvent printers. The vinyl’s coating accepts ink beautifully, ensuring crisp edges and rich colour saturation across your entire design.

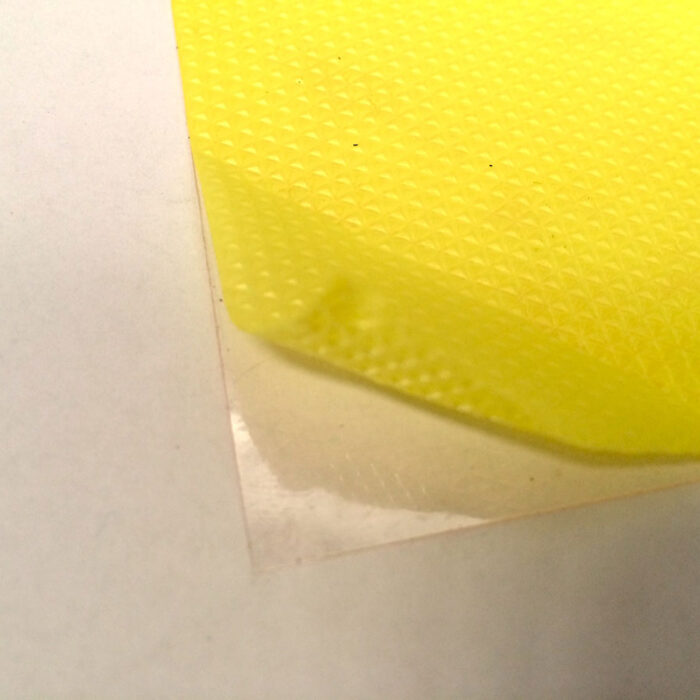

The 90-micron film sits on a slightly adhesive polyester carrier that revolutionizes your workflow. This innovative backing allows you to print and cut even the smallest details with precision, while the adhesive surface lets you reposition and secure tiny elements before transfer – eliminating the frustration of lost pieces during weeding.

Whether you’re producing custom t-shirts, athletic wear, or promotional apparel, Digital Invite Light delivers professional results with remarkable efficiency. This versatile vinyl adheres beautifully to cotton and polyester fabrics with excellent wash durability.

- Superior Detail Capability – The 90-micron thickness strikes the perfect balance between durability and precision cutting, enabling intricate designs and small text that other vinyls can’t achieve.

- Adhesive Carrier Technology – The slightly adhesive polyester backing is a game-changer for complex designs. Small cut pieces stay in place during weeding and can be repositioned before final application.

- Fast Weeding & Application – Designed specifically for speed, this vinyl weeds cleanly and quickly, reducing production time and labor costs – ideal for businesses handling large order volumes.

- Versatile Fabric Compatibility – Bonds securely to both cotton and polyester fabrics, giving you flexibility across different garment types and blends.

- Professional Finish Options – Choose between matte for a soft, subtle look or gloss for vibrant, eye-catching designs that pop.

- Excellent Wash Durability – Withstands repeated washing at 60°C when properly applied, ensuring your designs stay vibrant through many wear-and-wash cycles.

| Specification | Details |

|---|---|

| Composition | Polyurethane/COPES mixed film |

| Film Thickness | 90 microns |

| Carrier Material | Polyester with slight adhesive |

| Carrier Thickness | 100 microns |

| Finish Options | Matte and Gloss |

| Compatible Fabrics | Cotton, Polyester, and blends |

| Printer Type | Eco-solvent and Solvent printers |

| Application Temperature | 150°C (302°F) |

| Application Time | 12 seconds |

| Application Pressure | Medium (3-4 bar) |

| Peel Type | Hot peel |

| Wash Temperature | Up to 60°C (140°F) |

| Care Instructions | No dry cleaning, no tumble dry, wash inside-out |

| Minimum Cut Size | 0.5mm |

Step 1: Prepare Your Design

- After cutting, weed away excess vinyl while keeping your hand resting on the carrier

- Apply gentle pressure outward from the design to prevent small details from lifting

- For intricate designs with small details, use clear application tape to secure all elements

- For larger prints, yellow application tape is recommended for easier handling

Step 2: Transfer the Design

- Apply application tape firmly over your weeded design, burnishing well

- Turn the entire sheet over (flip it upside down)

- Remove the carrier backing from the back – NOT the application tape from the front

- This reverse method prevents small pieces from lifting during transfer

Step 3: Position on Fabric

- Preheat your heat press to 150°C (302°F)

- Pre-press the garment for 2-3 seconds to remove moisture and wrinkles

- Position your design on the fabric (it will be facing down with application tape on top)

- Ensure the design is exactly where you want it

Step 4: Initial Press

- Apply medium pressure (3-4 bar)

- Press for 12 seconds at 150°C (302°F)

- Maintain consistent, even pressure throughout

Step 5: Remove Carrier (Hot Peel)

- Immediately after pressing, while the material is still hot, carefully peel away the carrier film

- Peel slowly and steadily to ensure all vinyl has adhered properly

Step 6: Final Press for Maximum Durability

- Cover the design with silicone paper or Teflon sheet

- Press again for an additional 5-10 seconds at 150°C

- This second press ensures optimal adhesion and improves wash durability

- Allow the garment to cool completely before handling

Step 7: Curing and Care

- Wait 24 hours before the first wash to allow the adhesive to fully cure

- This waiting period is crucial for maximum wash durability on both cotton and polyester

Recently Viewed

For more information or to request a Brochure, call us on 02392 590 281