Talk to an expert

For more information or to request a Brochure, call us on 02392 590 281

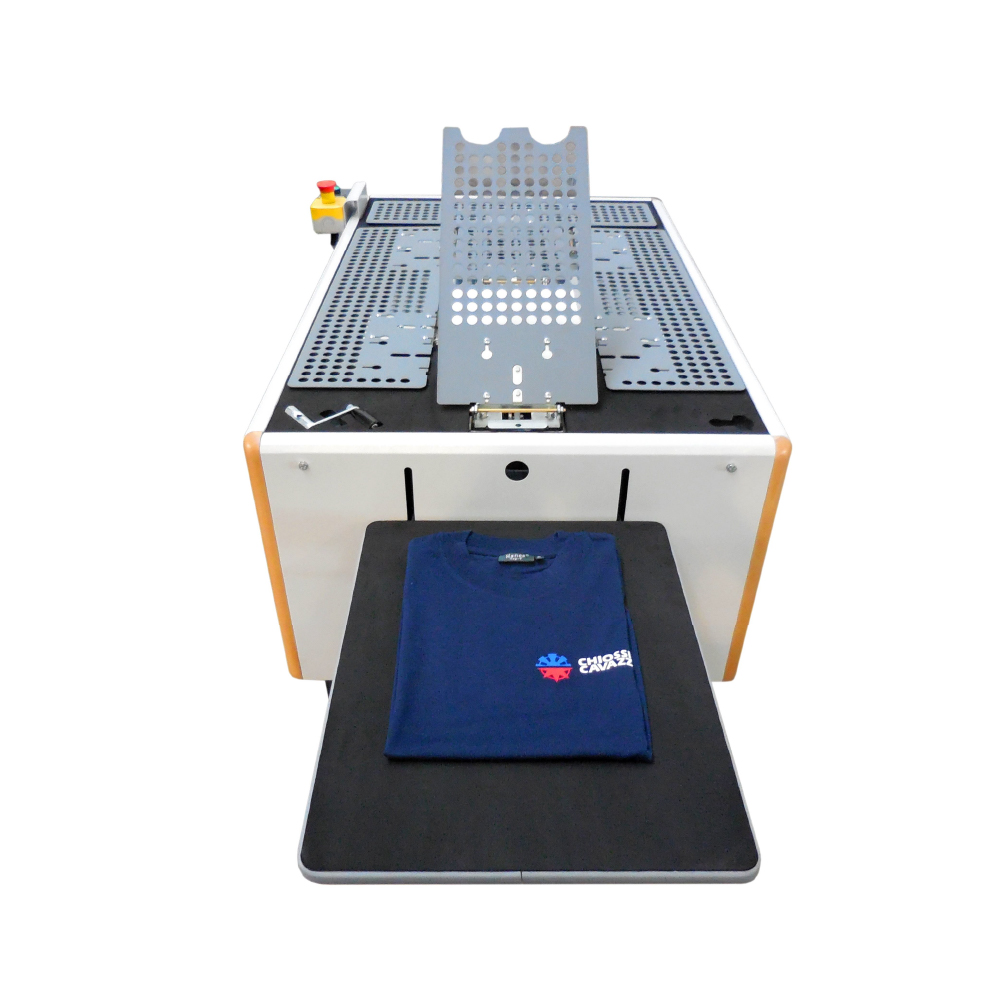

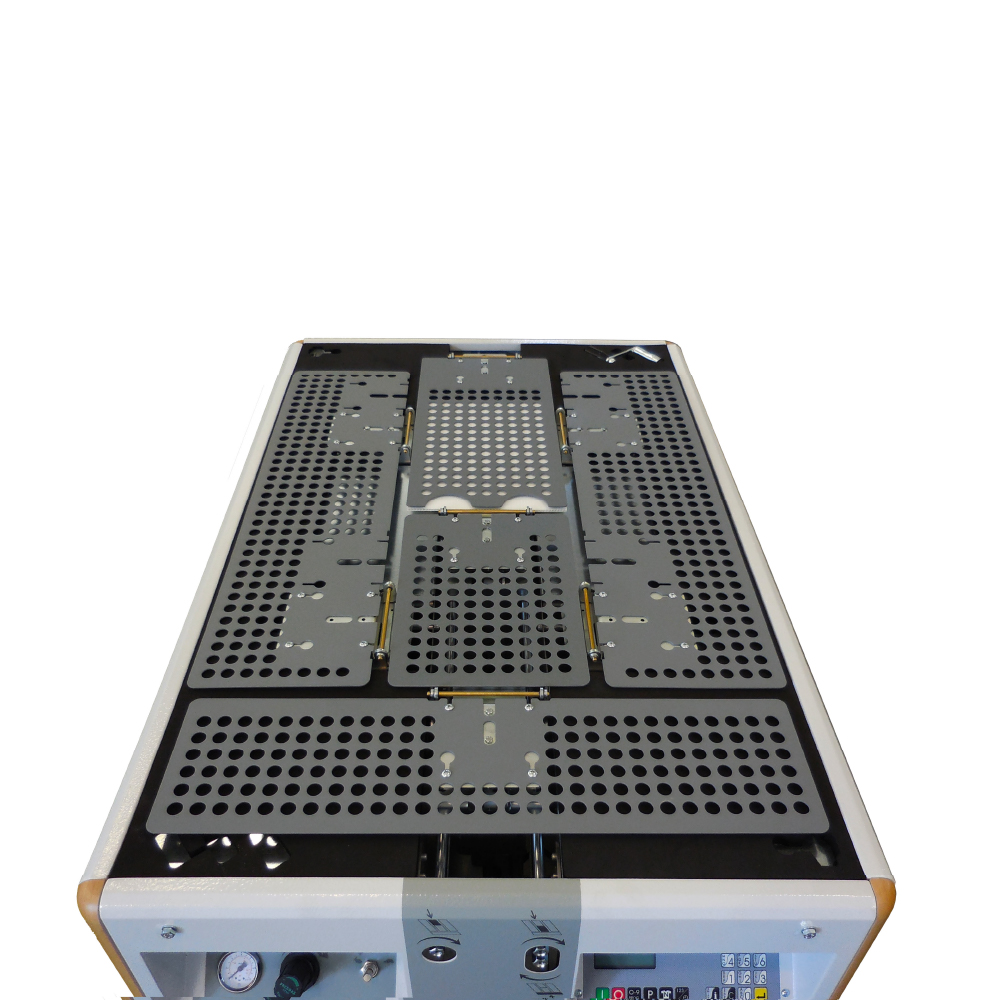

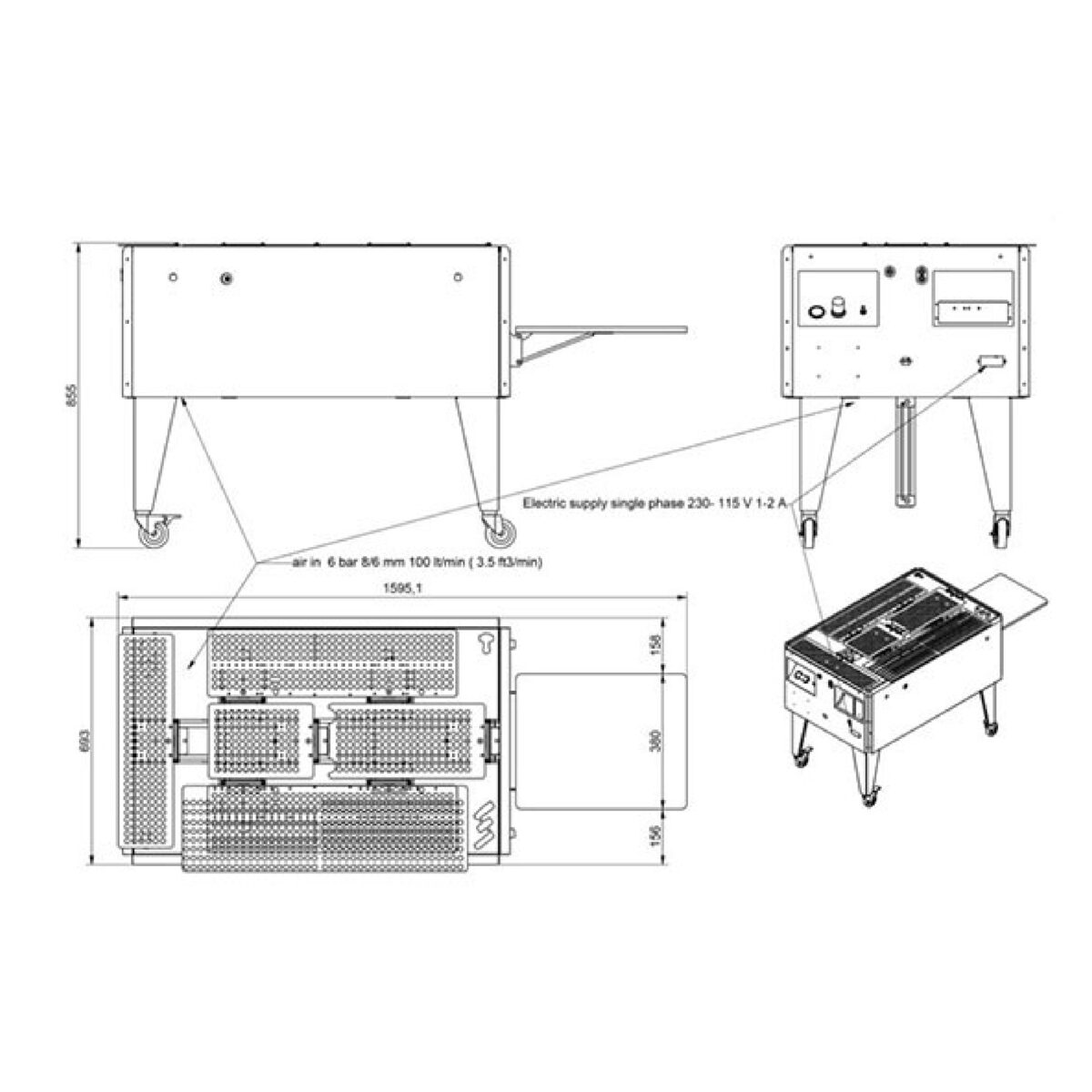

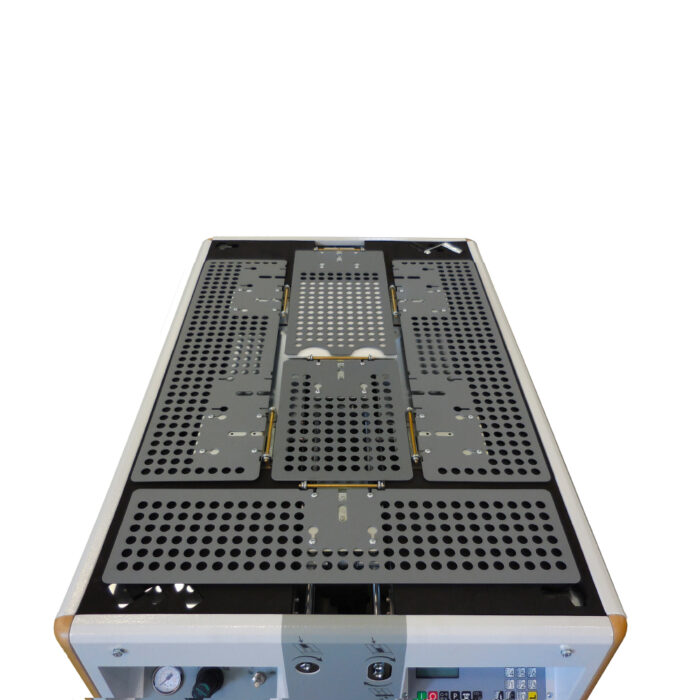

Speedy T Folding Machine

Semi-automatic packaging machine.

£9,000+VAT

Notice: Most inks, toners and consumables have expiry dates, please bear this in mind if ordering in bulk!

Forever transfers papers are only suitable for use with LASER PRINTERS.

- Description

- Specifications

Description

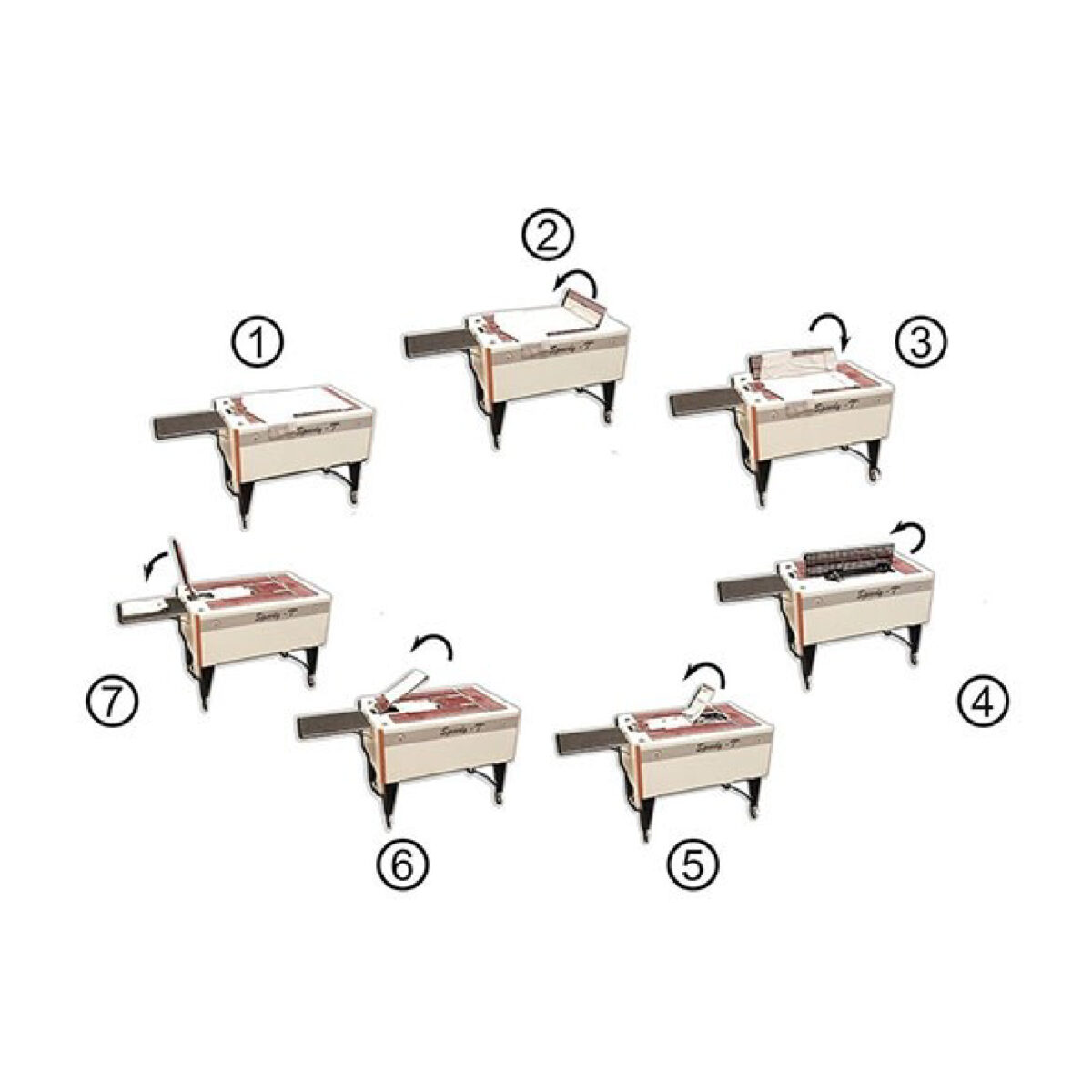

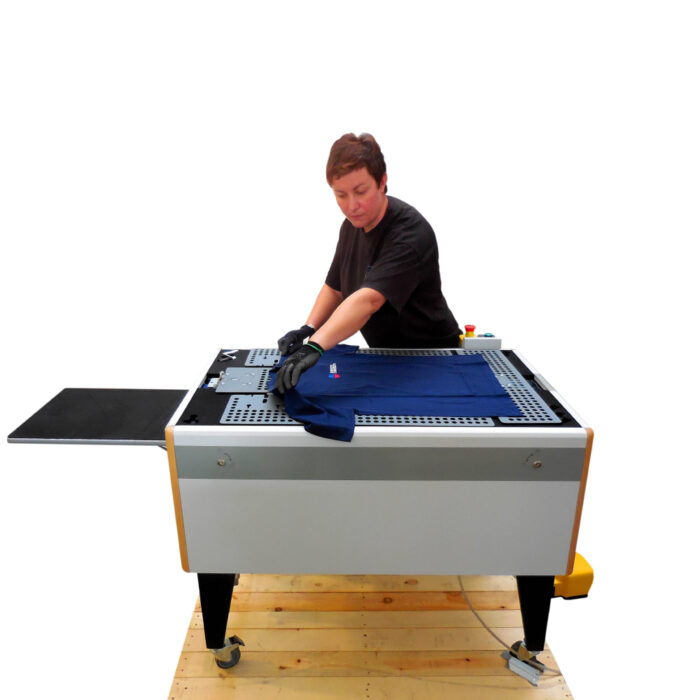

Folding Machine In Action

T-shirt folding and semi-automatic packaging machine

The SPEEDY – T is a folding and semi-automatic packaging machine. This product is indispensable for a fast and uniform folding of T-shirts, sweaters, hoodies and other garments. The blades are interchangeable, very easy to adjust and adapt the fold to the required size, changing in few seconds the set-up from baby t-shirts to extra large sizes. The factors of its success are the reliable fold quality combined with its heavy-duty production capability. It can be adapted to suit all shapes and sizes available on the market.

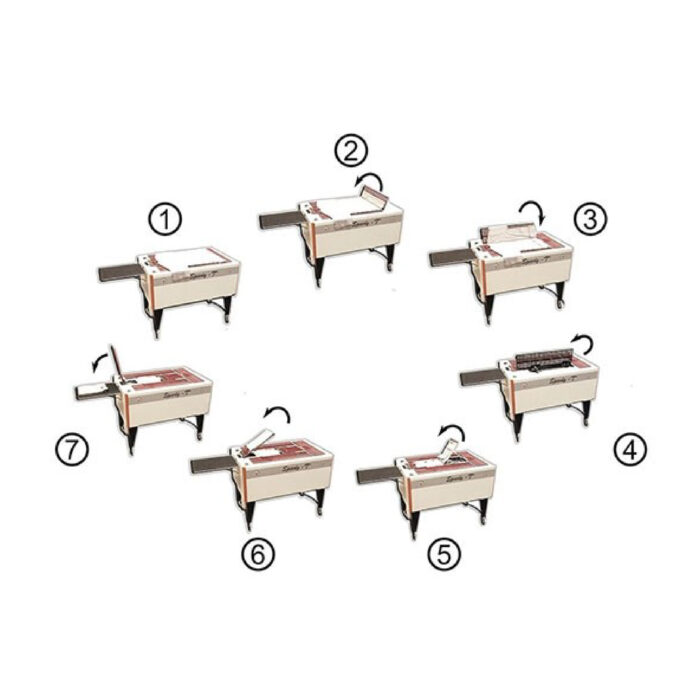

SPEEDY – T can operate in two ways:

Stacking mode: each folded garment is placed on the stacker, which descends automatically; a photocell indicates when the stack is at its maximum load and stops the machine.

Packaging mode: at the end of each work cycle the garment remains on the last blade, which is lifted up, and it can be easily packed in a bag.

Features:

The factors of the Speedy T’s success are the reliable fold quality combined with its heavy-duty production capability. With over 800 units in constant operation, working on 5 continents, this revolutionary machine grants exceptional saving in terms of time and logistic processes.

The moving blades have been redesigned and built with the new lightweight and resistant materials. A special anti-slip paint covers the surface, guaranteeing unseen results even with light or thin garments. The blades are placed on rails that can be adjusted in a few seconds without the need for further equipment, to ensure endless possibilities of folding and adapt to all sizes.

The exterior design has been completely transformed, thanks to a solid and compact structure, to make it easier to access internal components and simplify handling. The control panel has also undergone considerable optimisation thanks to a simple and intuitive keypad and an LCD equipped with diagnostic functions, production counting and 10 custom folding programs.

Advantages include:

- Stacker Mode with automatic photocell

- Packaging Mode with ergonomic lifting blade

- 10 folding programs

- In Customisation of folding programs

- Self-diagnostics of anomalies and faults

- Production count and report when has reached the preset number of pieces

- Hourly production programming with acoustic signal for productions below minimum threshold setting

- Language selection (Italian, French, English, Spanish, German)

- Reset function

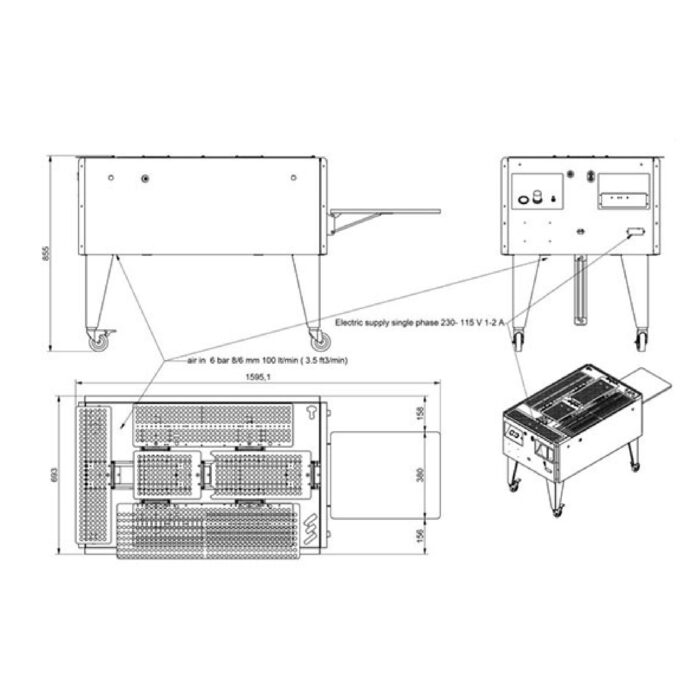

| POWER SUPPLY | 230/115 V + PE |

| POWER INPUT (max) | 230 W |

| REQUIRED AIR PRESSURE | 6 bar |

| AIR CONSUMPTION (max) | 50 l/min |

| WORK BENCH HEIGHT | 815 mm |

| TOTAL WIDTH | 710 mm |

| LENGTH WITH/WITHOUT STACKET LIFTED | 1500 / 1150 mm |

| T-SHIRT FOLDER WIDTH (min / max) | 150 / 350 mm |

| T-SHIRT FOLDER LENGTH (min / max) | 180 / 400 mm |

| WEIGHT | 90 kg |

| PRODUCTION WITH STACKER (max) | 500 pieces/h |

| PRODUCTION WITH PACKAGING (max) | 350 pieces/h |

| NUMBER OF PROGRAMS | 10 |

Recently Viewed

For more information or to request a Brochure, call us on 02392 590 281