Talk to an expert

For more information or to request a Brochure, call us on 02392 590 281

Schulze PRETREATmaker 5

£4,495.00 +VAT (£5,394.00 inc VAT)

Transform your DTG printing workflow with the PRETREATmaker 5, featuring revolutionary 5-nozzle SmartSpray technology that slashes pretreat liquid consumption by up to 30%. The generous 42 x 60 cm spray area handles everything from small items to larger garments, while the intelligent Auto Mode automatically calibrates spray amount to eliminate waste and ensure perfect coverage every time.

Experience effortless operation with the intuitive 7-inch touchscreen and contactless control. Smart maintenance notifications with digital tank monitoring keep your production running smoothly, while scan-to-spray barcode functionality streamlines your workflow. Deliver consistently brilliant colours, sharp details, and excellent washability with advanced pump technology engineered for professional operations demanding reliability and exceptional results.

RRP: £4,495 + VAT

Lease from £21 + VAT per week

- Description

- Specifications

Description

The Smart Way To PreTreat Textiles

Transform your textile printing operation with the PRETREATmaker 5, the smart solution for professional garment pretreatment. This advanced system sets new standards in efficiency, consistency, and ease of use for serious DTG printing businesses.

Every successful DTG print starts with proper pretreatment, yet it’s often where time and money are wasted. Inconsistent application leads to poor print quality, whilst over-spraying drains your budget and productivity. The PRETREATmaker 5 solves these critical challenges with intelligent automation that takes the guesswork out of pretreatment.

Revolutionary 5-nozzle SmartSpray technology automatically adjusts to your garment size, ensuring optimal coverage without waste—saving up to 30% on pretreat liquid costs. The result? Consistently brilliant colours, sharp details, and excellent wash durability on every print. Smart maintenance systems keep downtime to a minimum, whilst the intuitive interface means your team can achieve professional results from day one. Stop wasting time and materials on inconsistent pretreatment—invest in precision that pays for itself.

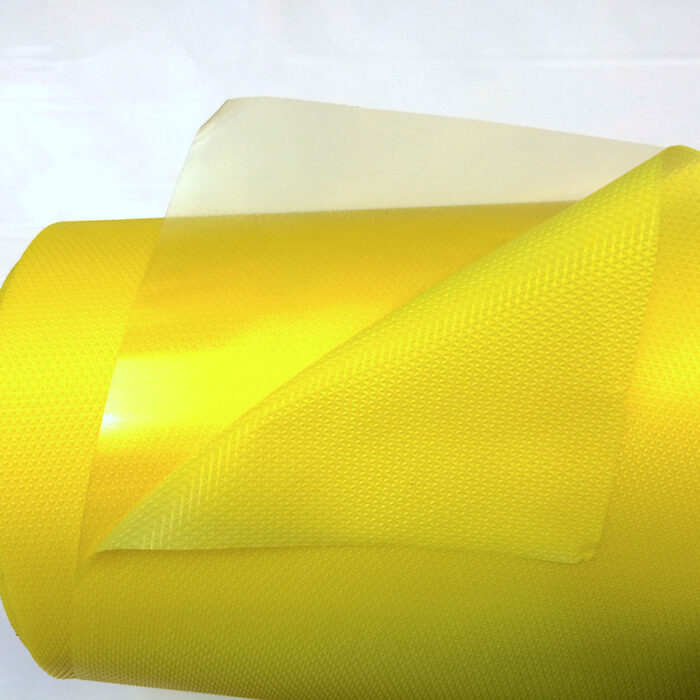

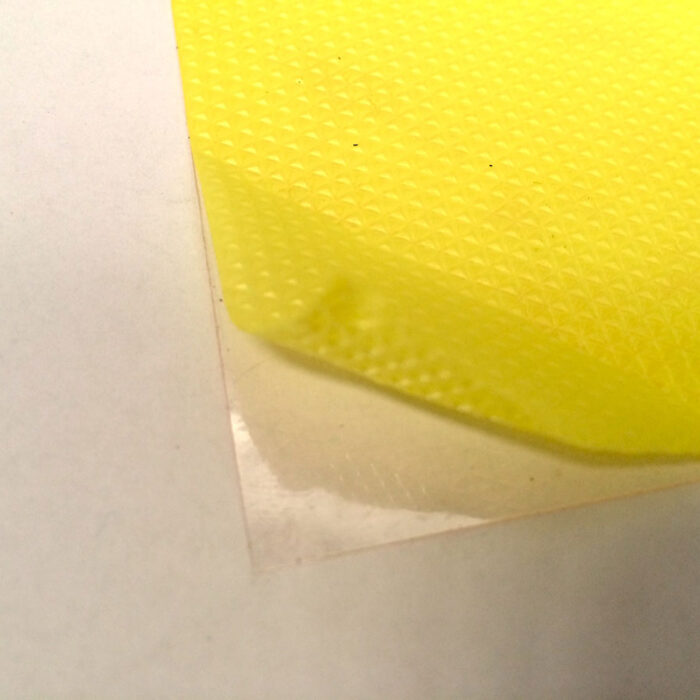

- 5-Nozzle SmartSpray System – Revolutionary spray technology reduces pretreat liquid consumption by up to 30% compared to 4-nozzle configurations while delivering superior coverage and consistency across the entire spray area.

- 42 x 60 cm Spray Area – Generous treatment zone accommodates a wide range of garment sizes from small items to larger pieces, maximizing production flexibility and eliminating the need for multiple positioning adjustments.

- Auto SmartSpray Mode – Calibrated automatic spray control adjusts application quantity precisely to the selected spray area, eliminating guesswork and material waste while ensuring optimal pretreatment for best printing results.

- 7-Inch Touchscreen Interface – Large, intuitive touchscreen with contactless touch-free button enables effortless operation and hygienic control, featuring easy navigation through spray settings, maintenance functions, and workflow automation features.

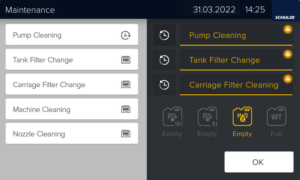

- Digital Smart Maintenance System – Comprehensive monitoring with real-time tank level displays, intelligent maintenance notifications, and automated cleaning routines minimize downtime and keep production running smoothly with proactive service reminders.

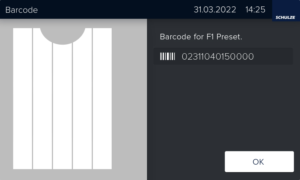

- Scan-to-Spray Barcode Functionality – Integrated barcode generator and scanner stores complete job settings for instant recall, streamlining workflow automation and ensuring consistent results across repeat orders without manual reconfiguration.

- Advanced Pump Technology – Enhanced pump system maintains constant pressure performance throughout operation, delivering consistently brilliant colours, sharp image details, and excellent wash durability with near-silent motor operation under 70 dB(A).

- Continuous long-format capability – MultiMark positioning system enables precise cutting of prints several metres long, perfect for large-scale production runs.

Save Pre-Treat. Minimize Costs.

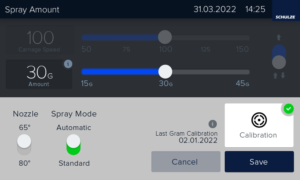

- Standard mode: Adjust the spray amount using only speed and direction.

- Auto mode: Calibrated smart spray mode where the spray amount is automatically adjusted to the chosen spray area.

- Use the Auto Smart Spray mode to always get the optimal spray volume for the best print results.

Quality and Consistency

- Consistently good spray results for brilliant colours, sharp details and excellent washability.

- Improved pump technology for constant pump pressure performance.

- Improved motor control for almost noiseless operation.

Automated Workflow

- Auto start up and shut down routine with nozzle check.

- Scan-to-Spray barcode feature.

- Barcode generator to simplify your workflow.

- Automated Start-Up and Shut-Down – Intelligent routines perform automatic nozzle checks during start-up and execute thorough pump cleaning during shut-down, ensuring the machine is always ready for optimal performance and extended component lifespan.

Less downtime. More spray time.

- Always have a perfect overview of the status of all important maintenance functions.

- Smart maintenance notifications remind you to perform important maintenance tasks.

- Digital level monitoring of all tanks.

- Full maintenance control.

Why Amaya?

Don’t just take our word for it.

Any company can sell a product, that is the easy bit. Amaya takes it to the next level, firstly with their due diligence, they will only sell you a product that is suitable for your business. Once you have the product the after sales service is something else. Combining on site product training on installation with continual free training days with industry specialists. I could not recommend Amaya enough for your next purchase to enhance your garment decoration business.

Always on hand with the best products and advice to grow, maintain and prosper with our printing and embroidery business. Their friendly service and prompt flexible attitude makes them second to none. If I could keep them a secret I would – I do not hesitate in recommending everyone at Amaya Sales UK.

Have used Amaya since 2003. Seventeen years !!! sheesh lol. They helped my business from day 1 and i am still running. Julian and co have been supportive throughout. We have exchanged several bottles of champers over the years as our families have grown. If you are seriously considering entering this business then i would highly highly recommend. You are not just buying a piece of machinery. You are buying a caring, rich in experience support network.

Amaya Uk have been beside us as a Company for over 17 years, and through that time they have always been there to offer advice and help. Through their excellent support we have grown not just in the world of Embroidery, but in printing through the various printing formats they offer. We have found them professional, caring and helpful, and always willing to go that extra mile to ensure we have what we want, not what they want. We can only thank them for all their help, and just wish we met them a lot earlier.

| Spraying area | 42 x 60cm |

| Number of nozzles | 5 |

| Number of pumps | 2 |

| Nozzle Material | Brass / stainless steel |

| Motor | Stepper motor |

| Dimensions | W 73 x D 98 x H 52 cm |

| Dimensions for transport | W 80 x D 95 x H 61 cm |

| Autom. Pretreat pump cleaning process | Yes |

| Auto nozzle cleaning option | Yes |

| Power consumption | 150 watts |

| Connection | 230 VAC (EU) or 110 VAC (US) |

Recently Viewed

For more information or to request a Brochure, call us on 02392 590 281