Talk to an expert

For more information or to request a Brochure, call us on 02392 590 281

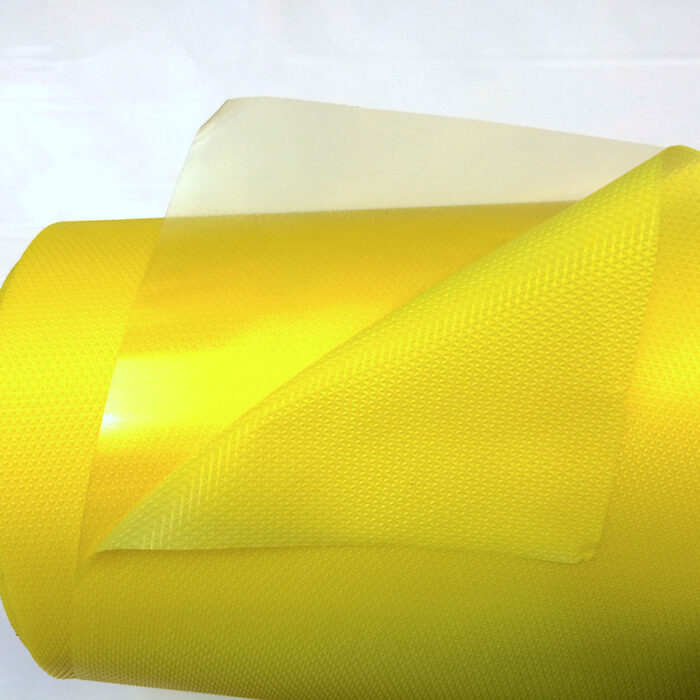

Membrane Base Plate for TC7, TS7, TPD7, TPD7 Premium

£495.00 +VAT (£594.00 inc VAT)

The Membrane Base Plate is a precision-engineered accessory designed to elevate heat press performance on all 40 x 50cm models like Secabo TC7, TC7 Lite, TPD7/Premium and TS7.

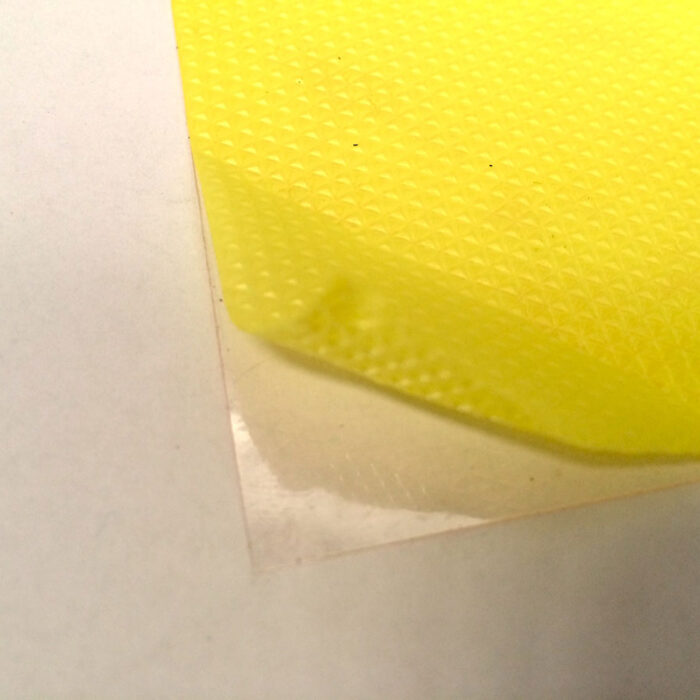

It uses an inflatable membrane to compensate for height differences and surface irregularities in transfer objects, ensuring consistent pressure distribution and accurate contact across the work surface.

Operators can easily set and read actual transfer pressure, fine-tune during pressing, and achieve reproducible results press after press.

Ideal for garment decorators tackling complex or uneven substrates, this base plate enhances control, improves transfer quality, and reduces material waste — making every heat press job more reliable and professional.

Recently Viewed

For more information or to request a Brochure, call us on 02392 590 281