Talk to an expert

For more information or to request a Brochure, call us on 02392 590 281

Secabo DTF MultiCut Pro

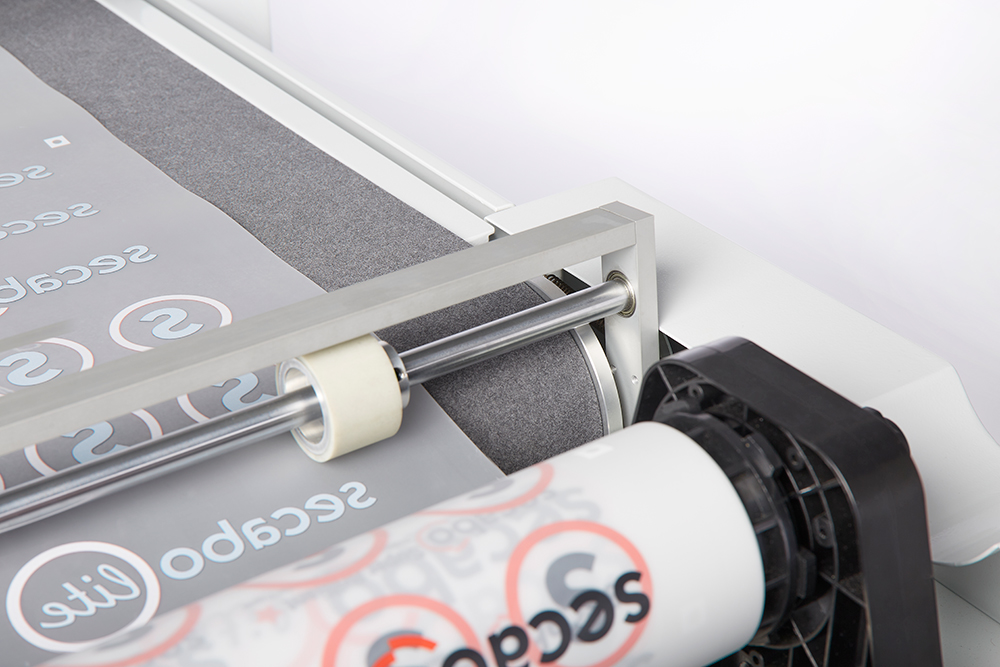

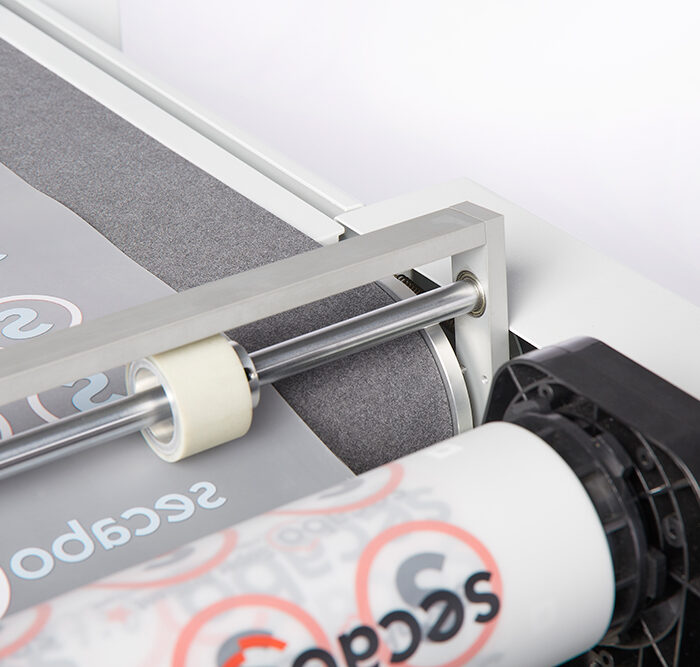

The Secabo DTF MultiCut Pro eliminates manual bottlenecks in your direct-to-film production. This intelligent flatbed plotter automatically feeds material from roll, scans positioning marks, and executes precision contour cuts—completely hands-free. With integrated QR code recognition, conveyor belt technology, and vacuum fixation, the MultiCut Pro handles everything from single transfers to multi-metre production runs without human intervention.

Stop sorting, stop manually feeding, stop wasting time. Whether you’re processing 1,000 identical logos or complex team shirt layouts with names, numbers, and sizes, this system cuts, perforates, and organizes your transfers in the exact sequence needed for application. Industrial-grade automation for DTF operations of any scale.

RRP: £10,995 + VAT

Lease from £52 + VAT per week

- Description

- Specifications

Description

Transform Your DTF Workflow with Full-Scale Automation

The Secabo DTF MultiCut Pro revolutionises direct-to-film workflows by automating the entire cutting process from roll to finished transfer. This advanced flatbed plotter combines intelligent feeding systems, precision cutting technology, and sophisticated software integration to eliminate manual intervention and dramatically increase production efficiency.

By automating feeding, cutting, and organisation, the MultiCut Pro transforms production speed and efficiency. What previously required hours of manual cutting and sorting now runs unattended, freeing your team to focus on pressing and order fulfilment. Process significantly larger orders in less time, reduce labour costs by up to 70%, and eliminate costly human errors – all whilst maintaining industrial-grade precision on every transfer. The result: faster turnaround times, higher output, and improved profitability.

- Automatic roll feeding system – Integrated conveyor belt feeds material up to 600mm wide, eliminating manual handling and enabling continuous production.

- QR code recognition technology – Automatic file allocation links cutting data to prints instantly, removing workflow bottlenecks and reducing errors.

- Matrix-Cut high-speed processing – Cuts identical transfers in optimised grids at up to 700mm/s for maximum efficiency in volume production.

- Intelligent perforation cutting – Cuts and organises complex multi-transfer layouts in application sequence, eliminating manual sorting for team and workwear orders.

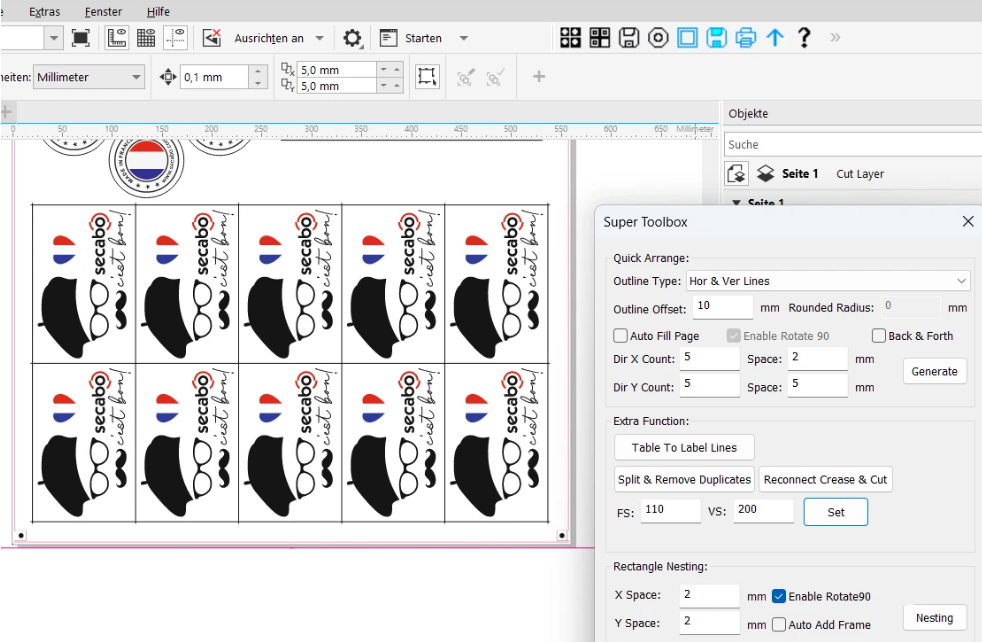

- Professional software integration – Direct compatibility with Digital Factory, Caldera, Ergosoft RIP software plus CorelDraw and Illustrator plugins for seamless workflows.

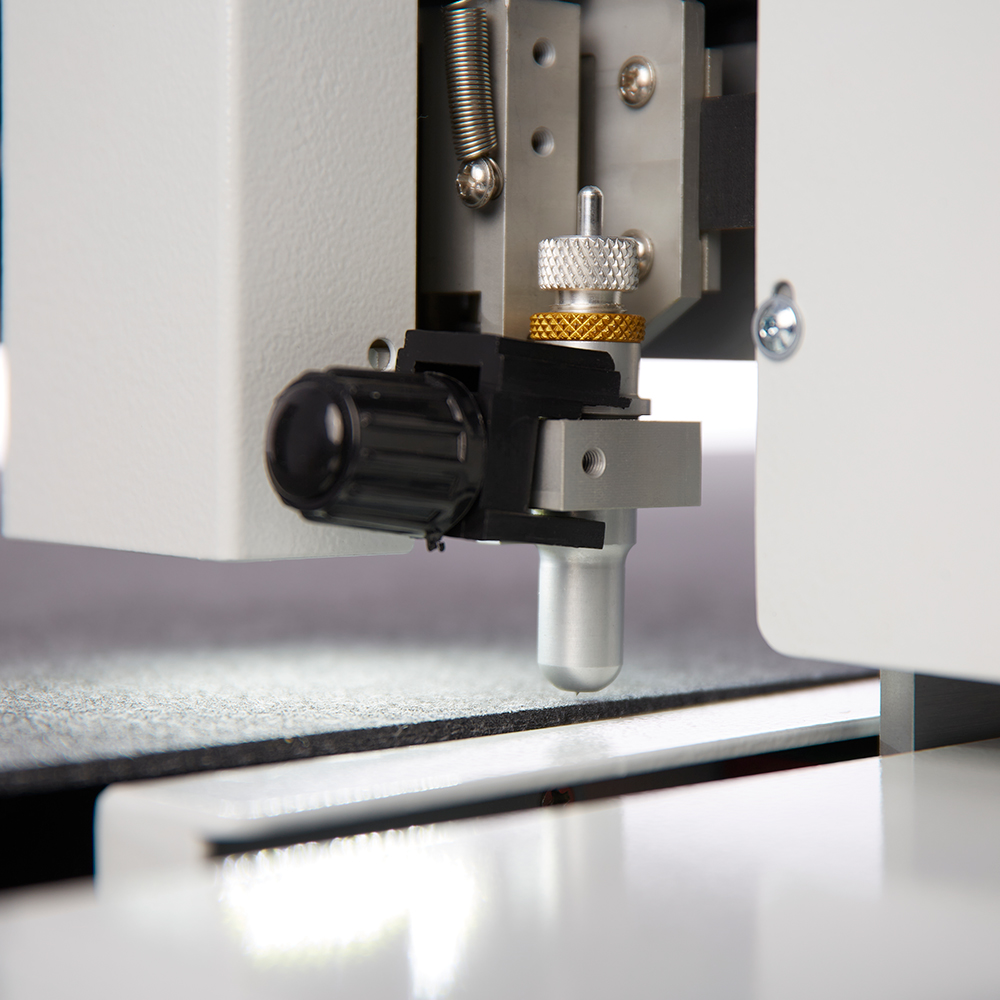

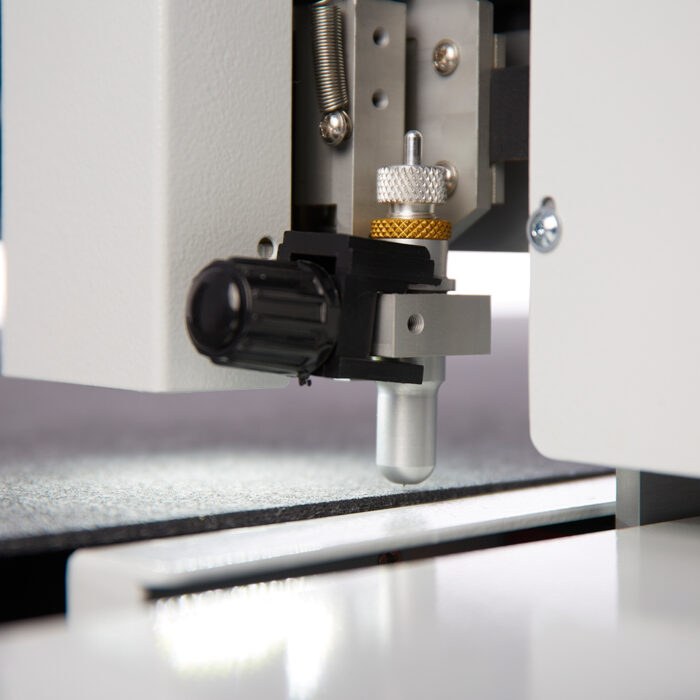

- Industrial-grade precision – Servo motor system delivers ≤0.05mm repeat accuracy with vacuum fixation for consistently perfect contour cuts on any transfer size.

- Multi-network connectivity options – Ethernet, WiFi, and USB stick operation provide flexible production control, enabling cutting from any workstation or direct from the machine.

- Continuous long-format capability – MultiMark positioning system enables precise cutting of prints several metres long, perfect for large-scale production runs.

Not Just Fast, But Lightning Fast!

The DTF MultiCut Pro processes typical areas of 600mm x 880mm in just 30 – 60 seconds. The integrated 7″ touch screen gives you full control to intuitively maximise your productivity and quality.

Perforation Cutting

The precise cutting and perforation functions of the MultiCut Pro ensure transfers not only remain perfectly cut, but also stay together exactly as they need to be applied later. This means no more tedious manual sorting – all transfers remain in the correct arrangement and can be processed directly.

Matrix-Cutting

Maximum efficiency for identical transfers, lightning fast, precise and perfect for large quantities, Matrix-Cut enables the automatic processing of many identical transfers in record time.

Workflow Made Easy

The versatility of the DTF MultiCut Pro goes beyond its cutting capabilities. Whether WiFi, Ethernet, USB cable or USB stick, its versatile interfaces make integrating it into your workflow a breeze.

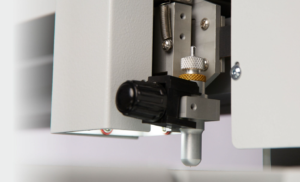

High Performance Camera

And it gets even better – the DTF MultiCut Pro is equipped with a high-performance camera that reads registration marks at lightning speed and automatically loads the corresponding cutting data. Whether you are working with DTF textile transfers, UV DTF self-adhesive films or dye-sublimation prints.

Software Integrations

The machine is compatible with leading RIP software solutions:

- Digital Factory (Fiery) – Optimised for excellent colour management and workflow automation.

- Caldera – Powerful RIP solution for extensive production workflows.

- Ergosoft – RIP software specially developed for textile printing for maximum precision.

Plug-ins are available for direct control from graphics programmes:

- CorelDraw – Simple creation of cutting lines and layouts with extensive productivity functions.

- Adobe Illustrator – Automated creation of cutting contours and nesting of designs.

| Motor | X-Servo motor; Y-Servo motor |

| Sensor | CCD Camera |

| Control Panel | 7 inch touchscreen |

| Tool Quantity | 1 |

| Tool Model | Blade / Pen |

| Media Hold Method | Vacuum Suction |

| Scanning Code Type | Mark or QR Code |

| Maximum Cutting Size | 640mm x 880mm |

| Scanning Speed | Approximately 5s |

| Cutting Speed | 10 – 700 mm/s |

| Cutting Force | 0 – 750g |

| Maximum Material Weight | Approximately 250g |

| Media Feeding Method | Auto Feeding System |

| Maximum Diameter of Paper Feed Roll | 200mm |

| Maximum Width of the Material Roll | 600mm |

| Weight with Packaging | 277.00 kg |

Recently Viewed

For more information or to request a Brochure, call us on 02392 590 281