Talk to an expert

For more information or to request a Brochure, call us on 02392 590 281

Kornit Presto S

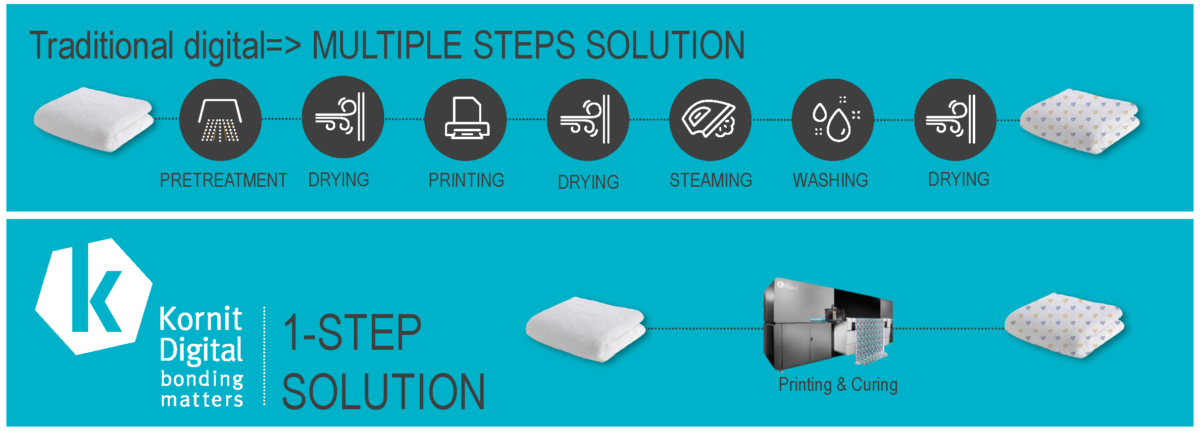

Introducing the most advanced single-step solution for direct-to-fabric printing.

Kornit Presto S is a one stop shop with one-step process to every fabric printing aspect and domain.

Like its former Allegro, the Kornit Presto S eliminates the need for external process steps, enabling you to achieve the best results from PFP (Prepared-For-Print) to finished digitally printed fabric faster than ever.

Now, with the new NeoPigment™ Robusto Softener, the Presto S is a complete solution for printing, softening and drying in a single step.

With no water waste and in the most smart and sustainable way, the Presto opens your market reach to a wide range of applications. From fashion, baby textiles to home décor, the Presto provides high quality prints, vivid colors and great hand-feel to multiple fabric types, on-demand.

Price on Application (POA)

Spread your payments with our Leasing and Finance facilities.

- Description

- Specifications

Description

Introducing the most advanced single-step solution for direct-to-fabric printing.

Kornit Presto S is a one-stop-shop with a one-step process to every fabric printing aspect and domain. Like its former Allegro, the Kornit Presto S eliminate the need for external process steps, enabling you to achieve the best results from PFP (Prepared-For-Print) to finished digitally printed fabric faster than ever.

With only minutes from file to finished fabric, and a true sustainable process, the Kornit Presto S roll to roll printer is the fastest, most cost-effective way to print on textile. The Presto system prints on multiple fabric types with just one NeoPigment™ Rubosto ink set. Kornit’s innovative and waterless printing solution includes patented Fixation on the Fly (FOF) meaning fixation fluids are injected through the print heads directly onto the fabric. As a result, all additional steps such as pre-and post-treatment are eliminated. Optimize your workflow and answer the call of your customer, the market, and the environment with the efficiency of the Presto S roll to roll fabric digital printing machine. The system is easily operated by a single person and is available in multiple speed and color configurations.

- Easy setup. All it takes is a single operator and a small space.

- The shortest time from file to finished goods

- Advanced curing mechanism

- Paired with the most robust ink set in the market – the NeoPigment Robusto

- Complete integration with web-to-print platforms

- No need for any external processes such as pre-treatment, steaming and washing

- Available in multiple speed configurations

- One ink set for any fabric type

- Fully automated production process

- Prints on a wide variety of fabrics, including synthetics, naturals and blends

- Easily print-to-cut

Advantages include:

- Single-step solution – an entire production process in one system.

- Faster than ever – advanced curing mechanism

- NeoPigment robusto – widest colour gamut in the R2R industry

- Face any surface – prints on a wide variety of fabrics

| PRINT HEADS | Per configuration |

| Ink TYPE | Kornit’s water-based NeoPigmentTM Robusto ink + Fixation agent (FOF) |

| PRINTING AREA | up to 180 cm / 70.8 in |

| WEIGHT | 4500kg / 9920.1lb |

| POWER REQUIREMENTS | 110/220V, 60/50 Hz, 40A, 3Ph+N+GND 25kW |

| COLOURS | Basic Configuration: Cyan, Magenta, Yellow, Black, Red, Green |

| MEDIA TRANSPORTATION | High-precision adhesive belt conveyor system |

| FABRIC FEEDING SYSTEM | Axial unwinding system with adjustable fabric width and tension mechanisms |

| MAX MEDIA THICKNESS | 15 mm / 0.59 in |

| MAX ROLL WIDTH | 180 cm / 70.8 in |

| MAX ROLL OUTER DIAMETER | 40 cm / 15.74 in |

| MAX ROLL WEIGHT | 50 kg / 110.2 lb |

| OPERATING SYSTEM | Compatible with any RIP software |

| COMPRESSED AIR | 6-8 bar/ ≤ 0.4 m3/min |

| DRYER TYPE | MCS- Modular Curing System |

Recently Viewed

For more information or to request a Brochure, call us on 02392 590 281